EnWave’s Patented Microwave Drying Technology to Accelerate Pharmaceutical Freeze-Drying Processes

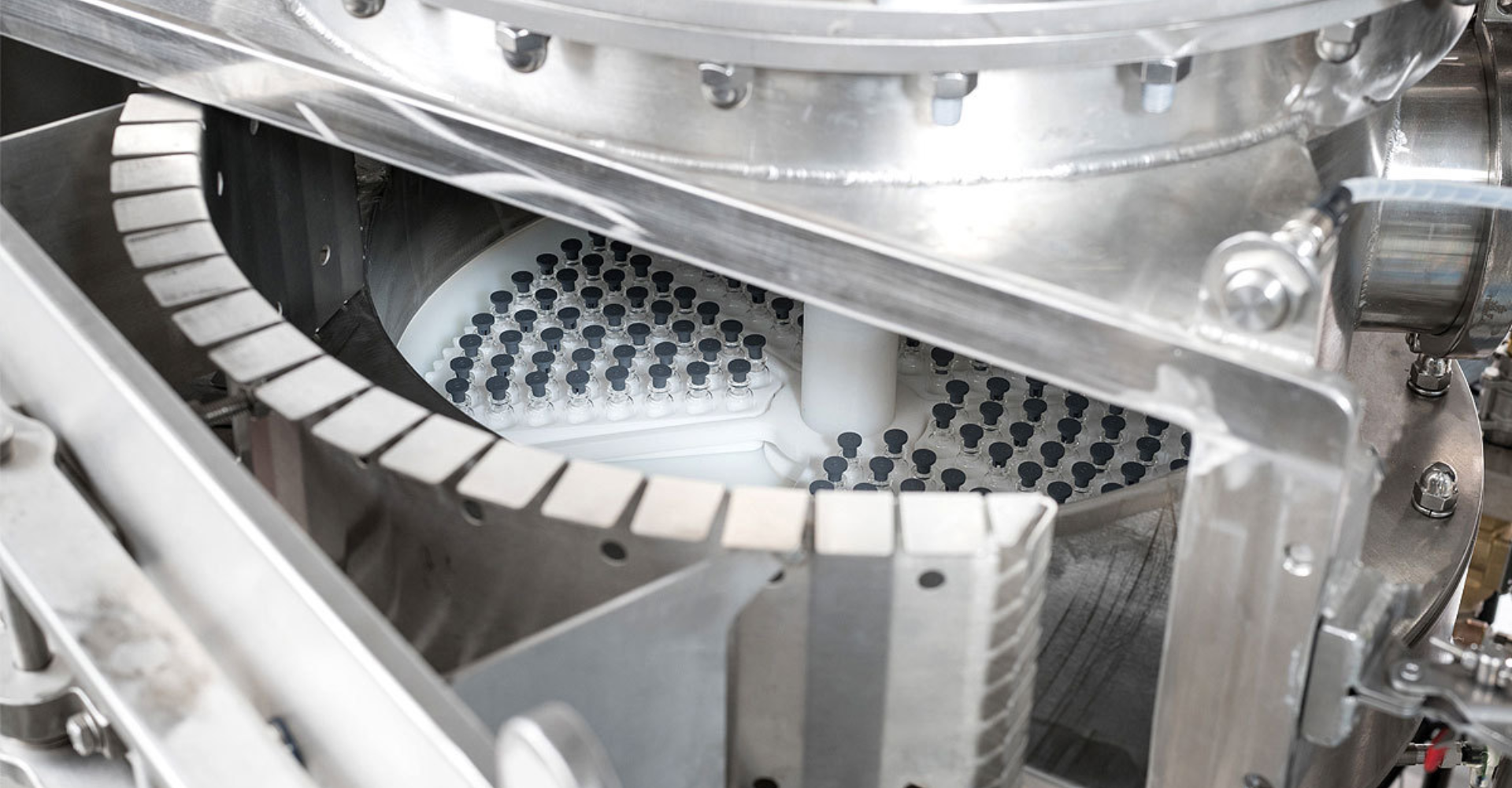

Freeze-drying, also known as lyophilization, is a common method for preserving and drying sensitive or delicate materials. However, the process can take a long time and can be energy-intensive. To address these challenges, researchers have been exploring the use of microwave energy to accelerate the freeze-drying process. In this article by GEA, a global technology company, we learn about the benefits and challenges of microwave-assisted freeze-drying (MAFD) and the company’s efforts to develop a commercial-scale MAFD system. While MAFD shows promise for reducing drying times and improving product quality, there are still some technical and regulatory hurdles to overcome before it can be widely adopted in the pharmaceutical and biotech industries.

Read the full article here.

About EnWave

EnWave is a global leader in the innovation and application of vacuum microwave dehydration. From its headquarters in Vancouver, BC, EnWave has developed a robust intellectual property portfolio, perfected its Radiant Energy Vacuum (REV™) technology, and transformed an innovative idea into a proven, consistent, and scalable drying solution for the food, pharmaceutical and cannabis industries that vastly outperforms traditional drying methods in efficiency, capacity, product quality, and cost.

With more than fifty royalty-generating partners spanning twenty countries and five continents, EnWave’s licensed partners are creating profitable, never-before-seen snacks and ingredients, improving the quality and consistency of their existing offerings, running leaner and getting to market faster with the company’s patented technology, licensed machinery, and expert guidance.

EnWave’s strategy is to sign royalty-bearing commercial licenses with food and cannabis producers who want to dry better, faster and more economical than freeze drying, rack drying and air drying, and enjoy the following benefits:

• Food and ingredients companies can produce exciting new products, reach optimal moisture levels up to seven times faster, and improve product taste, texture, color and nutritional value.

• Cannabis producers can dry four to six times faster, retain up to 20% more terpenes and 25% more cannabinoids, and achieve at least a 3-log reduction in crop-destroying microbes.

Learn more at EnWave.net.