What is drying in food processing?

Drying is one of the oldest and most fundamental methods of food preservation. From sun-dried fruits to commercial dehydrated snacks, drying has played a critical role throughout history in enhancing food safety, extending shelf life, and maintaining quality. In modern food processing, drying continues to evolve with innovative technologies driving improvements in product development, nutrition, and sustainability.

Understanding the role of drying technology in food processing helps manufacturers, startups, and innovators make informed decisions that can elevate product performance and consumer appeal. This blog explores the core principles of drying, common techniques including freeze drying and microwave dehydration, the challenges traditional drying methods face, and how EnWave’s microwave dehydration technology is revolutionizing the industry.

Why drying matters in food processing

At its core, drying removes moisture from food, halting spoilage caused by microbial growth and enzymatic activity. Moisture content is a critical factor in determining a product’s shelf life and safety. Removing or significantly reducing water content inhibits bacteria, molds, and yeasts from multiplying, preserving food’s edibility for extended periods.

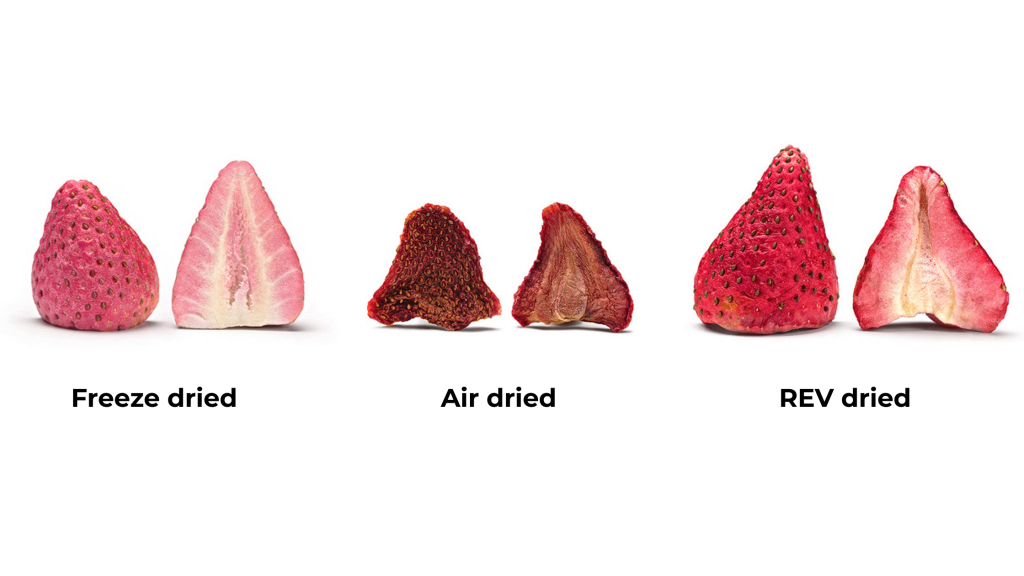

Beyond preservation, drying influences texture, taste, nutritional content, and appearance. Achieving the right balance during drying requires controlling temperature, rate of moisture removal, and the drying environment to prevent undesirable changes like nutrient loss, discoloration, or textural degradation.

Breaking down the science of drying simply

Food drying transfers heat to the product, causing water molecules to evaporate. The method and conditions used can cause variations in the quality attributes of the final dried product.

Drying consists of:

- Drying rate: How quickly moisture leaves the food

- Temperature: Controlled to avoid overheating and nutrient destruction

- Airflow and pressure: Affect how vapor escapes and moisture is removed

Depending on the approach, drying can be slow, taking hours or days, or fast, completed in minutes. Faster drying often retains more nutrients and better sensory properties since food spends less time exposed to heat and oxygen.

Common drying techniques

Food processors typically choose among several drying methods, each with unique advantages and limitations.

- Sun drying and air drying: Traditional, low-cost methods involving natural airflow and heat. These are inexpensive but weather dependent, slow, and highly variable in quality.

- Freeze drying: This cutting-edge method freezes the product and removes moisture via sublimation under vacuum, preserving structure, flavor, and nutrients intensely well. However, it’s energy-intensive, costly, and slow.

- Microwave dehydration: A fast, energy-efficient process where microwaves heat and evaporate moisture under vacuum. EnWave’s Radiant Energy Vacuum (REV™) technology is a leader in this space, providing excellent nutrient and flavor preservation with dramatically reduced drying times.

Challenges with traditional drying methods

Despite their widespread use, conventional drying processes face notable challenges:

- Long drying times delay product throughput and increase processing costs.

- High energy consumption drives up operational expenses and environmental footprint.

- Nutrient degradation can result from prolonged heat exposure.

- Inconsistent product quality due to uneven drying and variable moisture removal.

These factors present obstacles to scaling, cost optimization, and innovation in food product development.

Next-generation drying technology

EnWave’s REV™ microwave dehydration technology addresses many challenges faced by traditional drying methods. By applying microwave energy under vacuum, REV™ heats foods volumetrically (deep within rather than just on the surface) causing rapid and uniform moisture removal.

Key benefits include:

- Efficiency and speed: Processing times observed to shorten from days (freeze drying) to under an hour.

- Retention of nutrients and flavor: Shorter drying exposure helps preserve vitamins, antioxidants, and natural sensory compounds.

- Consistent product quality: The process allows precise moisture content control, supporting shelf stability and consumer expectations.

- Energy savings: Microwave dehydration consumes significantly less power compared to freeze drying, contributing to sustainability goals.

Data from comparative studies underscore these claims, showing microwave-dried products maintain vibrant colors and rich flavors, often superior to those freeze dried while offering substantial reductions in cost and time.

Practical value for startups and manufacturers

Understanding drying technology empowers food startups and manufacturers to make smarter product development decisions. Choosing the right drying method influences not just nutrition and quality but impacts packaging, shelf life, regulatory compliance, and market positioning.

Brands seeking to innovate should evaluate technologies like EnWave’s REV™ that offer rapid turnaround times alongside consistent output, energy savings, and the ability to scale from pilot to commercial facilities seamlessly.

Partnering with EnWave

EnWave invites food innovators to explore how microwave dehydration can transform their product development and commercial food drying operations. Whether interested in demos, pilot runs, or technical guidance, our team is ready to help you harness drying technology that benefits your bottom line and consumers alike.

Discover more at enwave.net and start advancing your food innovation journey today.