Popular food drying processes explained

Food drying is essential for preserving flavor, nutrition, and extending shelf life. This guide explains popular drying processes such as spray drying, air drying, freeze drying, and vacuum microwave drying with Enwave REV™. It details how each method works, ideal applications, advantages, and differences to help manufacturers make informed product development decisions.

Quick Overview

Drying removes moisture to stabilize foods. Spray drying suits liquid products creating powders, air drying fits tough foods, freeze drying offers premium nutrition and texture, and vacuum microwave drying rapidly processes foods with nutrient retention. Each method delivers unique benefits for specific product types and manufacturing needs.

How Does Spray Drying Work and What Products Use It?

Spray drying turns liquids like milk or fruit juice into powders by spraying droplets into hot air (150-200°C). The moisture evaporates instantly, producing fine and uniform powders. Common in dairy powders, coffee, flavorings, and powdered drink mixes, spray drying offers fast processing but uses high heat that reduces nutrient content and can alter flavor.

- Best for stable liquids or emulsions

- Produces consistent powder particle size

- Not suited for heat-sensitive ingredients due to thermal degradation

How Is Air Drying Used in Food Processing?

Air drying uses heated air (50-70°C) to gradually remove moisture over several hours. It fits hardy vegetables, grains, and herbs where texture recovery is less critical. Air drying has low equipment cost but risks uneven drying and nutrient loss due to heat exposure and oxidation.

- Suitable for robust products like herbs and grains

- Cost-effective but nutrient loss can be high

- Can cause case hardening or tough textures

What Are the Advantages of Freeze Drying?

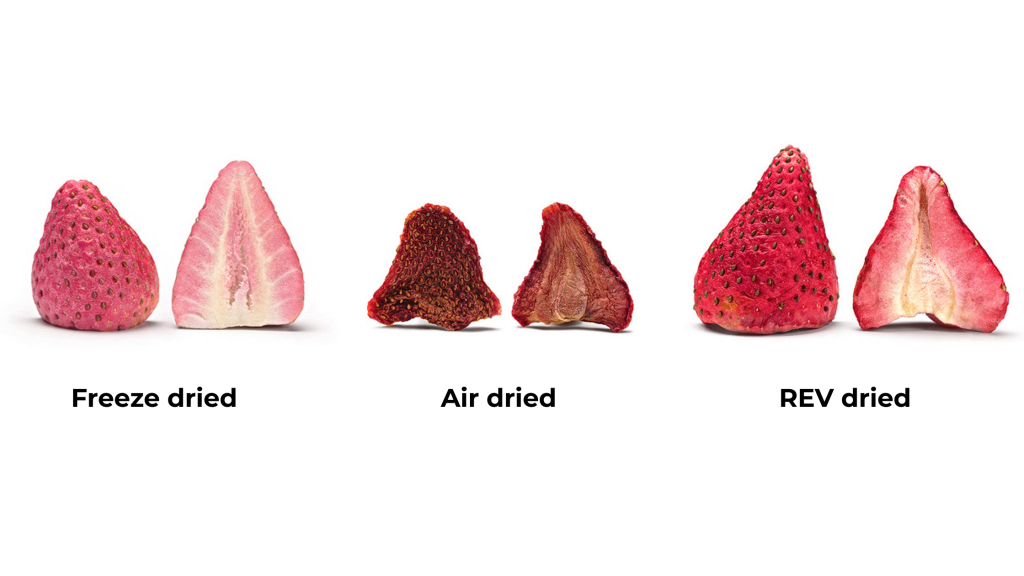

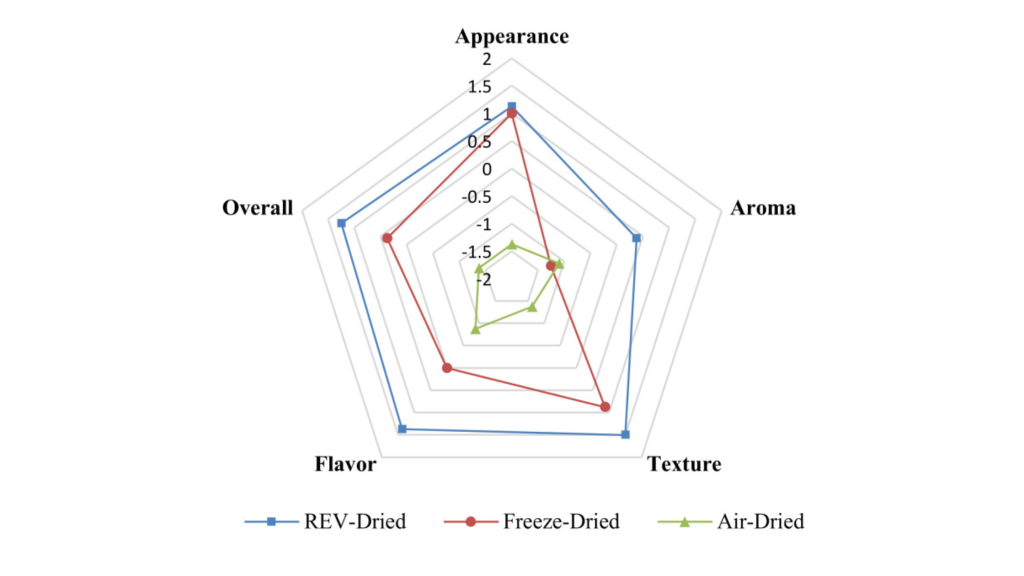

Freeze drying freezes foods and uses vacuum to sublimate ice crystals at very low temperatures (below -40°C). This preserves cellular structure, vitamins, and flavors, giving light, porous products ideal for aerospace, military rations, and premium snacks. Despite exceptional nutrient retention (90-97%), freeze drying is slow (24-48 hours) and energy intensive.

- Preserves most nutrients, texture, and flavor well

- Achieves long shelf life and rehydration quality

- High capital and operational cost

- Limited batch scalability affects innovation speed

How Does Enwave REV™ Vacuum Microwave Drying Transform Food Drying?

Enwave’s REV™ technology uses microwave energy combined with vacuum to gently and rapidly evaporate moisture volumetrically within 10-60 minutes. Its low temperature and controlled vacuum protect vitamins, colors, and flavor compounds while delivering dense, customizable textures ideal for snacks, powders, and specialty foods.

- Dries 28 times faster than freeze drying

- Retains 90-97% nutrients comparable to freeze drying

- Energy consumption is 70-90% lower than freeze drying

- Scalable from R&D to industrial volumes

Detailed Comparison of Drying Methods

| Feature | Spray Drying | Air Drying | Freeze Drying | Vacuum Microwave Drying (REV™) |

|---|---|---|---|---|

| Typical Drying Time | Minutes | 10 – 18 hours | 24-48 hours | 10-60 minutes |

| Process Temperature | 150-200°C | 50-70°C | Below -40°C | 30-50°C under vacuum |

| Nutrient Retention | Low to Moderate | Moderate | High (90-97%) | High (90-97%) |

| Energy Consumption | Moderate | Moderate | High | Low |

| Texture Quality | Fine powders | Variable | Light, porous | Dense, customizable textures |

| Typical Applications | Powders, beverages | Herbs, grains | Emergency rations, premium snacks | Fruits, veggies, meats, dairy, powders |

Why Does Nutrient Retention Matter?

Consumers demand nutrient-dense foods retaining vitamins, minerals, and antioxidants. Heat and oxygen exposure degrade key nutrients during drying. Enwave REV™ reduces time and oxygen exposure, preserving bioactive compounds essential for health benefits and clean-label claims.

Energy Efficiency and Sustainability

Freeze drying requires high energy for freezing and vacuum pumps over many hours, making it costly and environmentally intensive. Enwave microwave vacuum drying dramatically decreases energy use by targeting moisture directly, aligning with sustainability goals and reducing production costs.

How to Choose the Right Drying Method?

Consider product type, sensitivity, desired shelf life, texture, production volume, and budget. Freeze drying suits ultra-premium, fragile products. Air drying is economical for hardy ingredients. Spray drying works with liquids. Vacuum microwave drying is versatile, combining fast drying with superior nutrient retention, ideal for innovative product development.

Real-World Applications of Enwave REV™ Drying

Top brands use Enwave technology for fruit chips rich in antioxidants, tender jerky without toughness, and nutrient-dense powders for supplements. The technology supports clean-label, functional, and plant-based trends by preserving natural colors and flavors. See some of the brands we’ve worked with in our case studies page.

Frequently Asked Questions

What drying method best preserves nutrients?

Freeze drying and vacuum microwave drying retain 90-97% of nutrients, preserving more than air or spray drying.

Is microwave vacuum drying suitable for delicate products?

Yes, vacuum and low heat protect sensitive foods like berries and leafy greens.

Can vacuum microwave drying reduce production time?

Yes, it dries foods up to 28 times faster than freeze drying.

How do drying methods impact flavor and texture?

Freeze drying creates airy textures, air drying can cause toughness, while vacuum microwave drying customizes textures from crispy to chewy.

What energy savings does vacuum microwave drying offer?

It consumes up to 90% less energy compared to freeze drying.

Conclusion

Food drying technology has evolved. While freeze drying remains a top-quality option, Enwave’s REV™ vacuum microwave drying matches nutrient retention and quality while slashing processing time and energy use. This makes Enwave a leader in innovative, efficient commercial food drying that supports rapid product development and sustainability.

Further Reading:

EnWave Freeze Drying vs Microwave Drying:

https://www.enwave.net/freeze-drying-vs-microwave-drying/enwave

Green Thumb Depot, Nutrient Retention in Freeze Drying:

https://greenthumbdepot.com/blogs/guides/does-freeze-drying-remove-nutrientsgreenthumbdepot

ScienceDirect Advances in Vacuum Microwave Drying Systems:

https://www.sciencedirect.com/science/article/abs/pii/S092422442100491Xsciencedirect