REV™ uses a combination of Vacuum & Microwave energy, which results in a rapid, gentle drying process. By controlling the pressure and microwave power density, one can effectively control both the temperature and the final moisture of the product. Adding microwave energy to the drying process allows for an efficient energy transfer where the energy is absorbed by the material volumetrically, promoting a uniform dehydration process.

What is REV™?

REV™ stands for “Radiant Energy Vacuum.” It’s our own patented process of vacuum microwave drying that dehydrates food and plants more efficiently and of a higher quality than ever before.

See the results in person!

Book a Discovery Call today.

The benefits of REV drying

Efficient, gentle drying

Suitable for nearly every organic material

Precise moisture control

Closed-loop, volumetric drying

Less waste

Upcycle lower grades and reduce microbes

Superior quality retention

Keep natural colors, flavors, and nutrients

Optimized floor space

Use a fraction of the space of other drying methods

Minimal carbon footprint

Zero hazardous materials, zero chemicals, zero GHG emissions

From fresh to dry in hours, not days.

But don’t take our word for it. See before and after images below.

How does REV drying work?

Radiant Energy

- Fast and uniform volumetric heating

- Precise temperature regulation, process control and customization

- Fresh to dry in a fraction of the time

Vacuum

-

Lower boiling point for efficient,

low-temp processing - Quick dehydration without cooking

- Closed system captures volatilized components

- Add a pleasing puff to your products

REV-Dried

Strawberries

Moisture level: 40%

Drying time: 30 mins

Use: Snacks, Ingredients

EnWave gives you two ways to dry

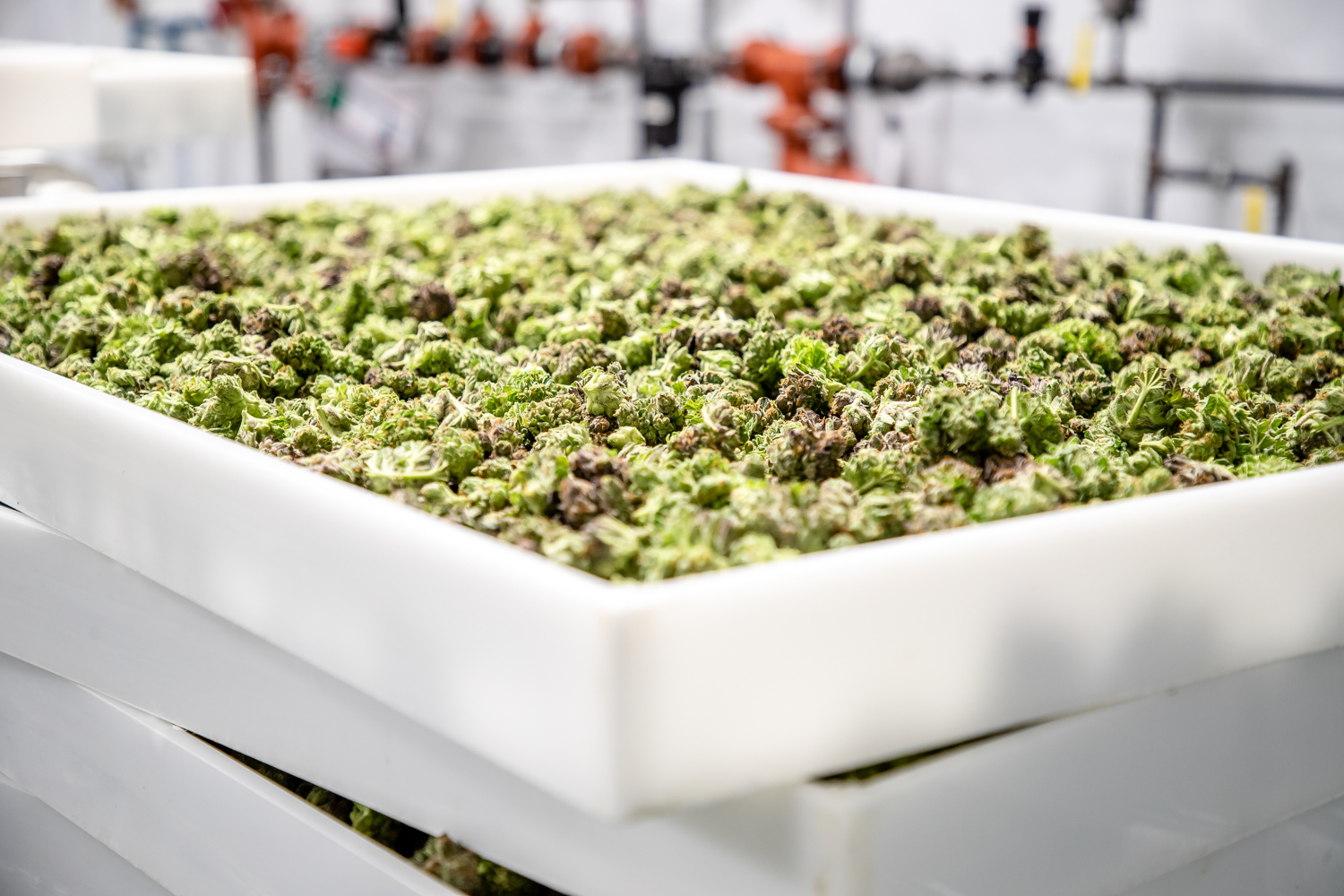

Tumble Drying

Tumble your product inside rotating drums within the vacuum microwave chamber for fast and consistent dehydration with a precise residual moisture content. Perfect for dehydrating heartier fruits, vegetables, grains, and dairy products, and producing dried fruit, meats, dairy products and spices. Plus, you’ll have greater control with an integrated HMI and PLC system.

Tray Drying

Gently dry your delicate products within microwave-transparent trays that continuously move through the drying chamber. Loading and unloading under ambient pressure is quick and easy. REV Tray Drying is perfect for more fragile fruits and flowers, complex baked goods, and crumbly dairy products.

REV technology scales with your business

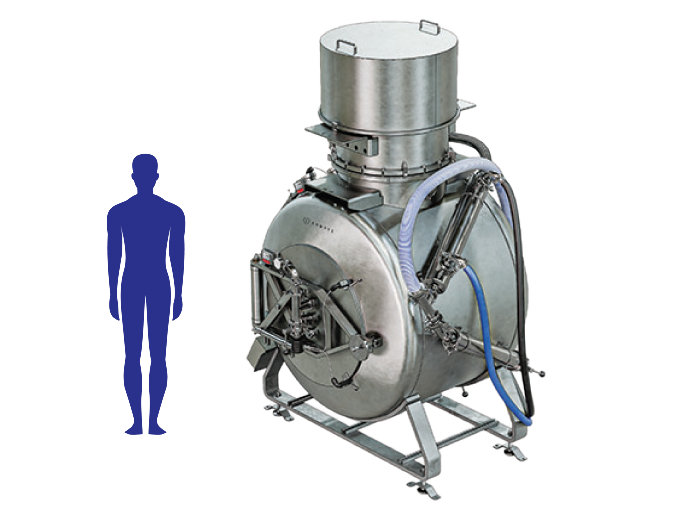

BEST FOR

R&D and small-scale producers

REV10 kW

Water

Removal: 9 kgs/hour

Freq: 2450 mHz

Vacuum: 22-280 Torr

Size: 6.56 x 5.25 x 8.50 ft

(2.0 x 1.6 x 2.6 m)

Ceiling: 11 ft (3.35 m)

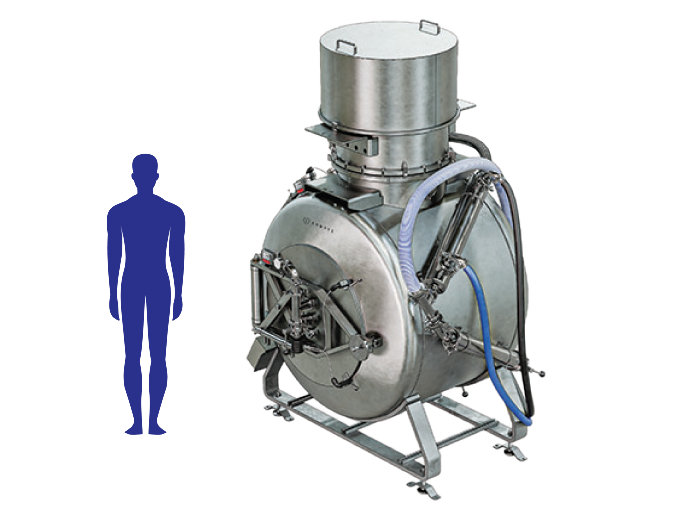

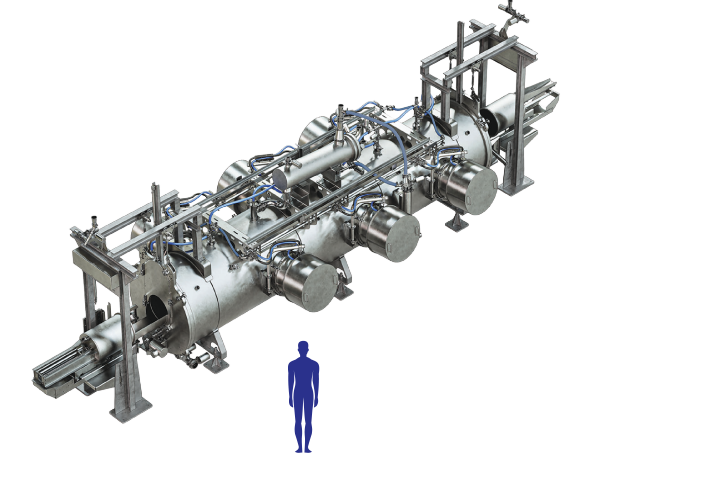

BEST FOR

large-scale producers

REV60 kW

Water

Removal: 40 - 50 kgs/hour

Freq: 2450 mHz

Vacuum: 22-280 Torr

Size: 38 x 11 x 11.15 ft

(11.6 x 3.35 x 3.4 m)

Ceiling: 15 ft (4.6 m)

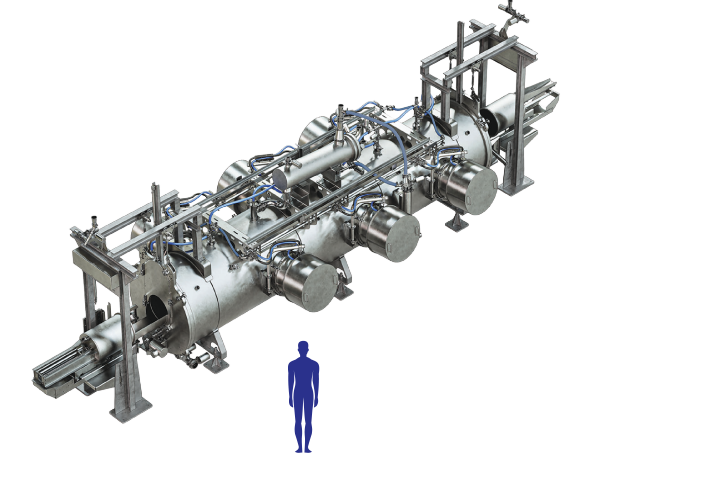

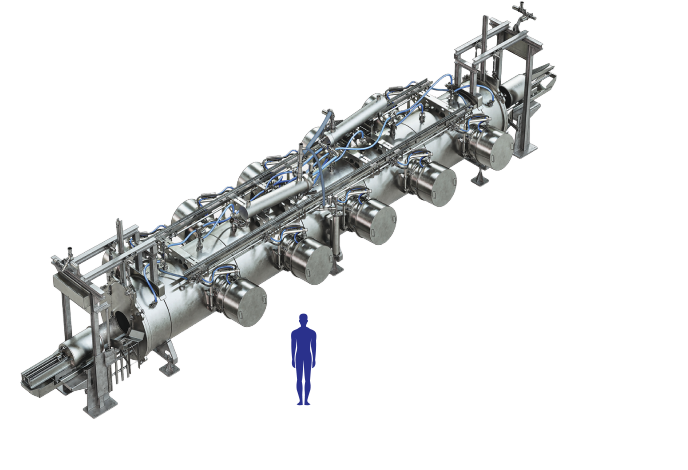

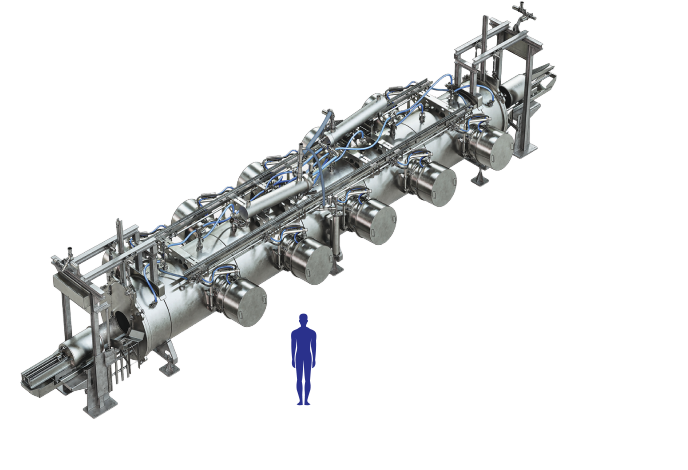

BEST FOR

industry leaders

REV100 & REV120 kW

Water

Removal: 80 - 83 kgs/hour

Freq: 2450 mHz

Vacuum: 22-280 Torr

Size: 50 x 11 x 11.5 ft

(15.24 x 3.35 x 3.5 m)

Ceiling: 15 ft (4.6 m)