The drying process can be a heavy burden for most large cannabis cultivators. It takes forever, costs a a small fortune in labour, and the necessary dry rooms take up too much valuable space. That’s where we come in. EnWave’s Radiant Energy Vacuum (REV) technology transforms a 7-14 day process into a consistent 2-hour drying cycle that has been clinically proven to increase product potency, aroma and aesthetics, and decrease contamination risk.

Premium Cannabis

Dries so fast,

it’s almost unfair.

What if you could go from harvest to cure on the same day? Now you can get to market faster and leave your competitors in the dust, with the help of EnWave experts and our REV™ technology.

Our innovative drying technology and expert guidance helps cultivators produce premium quality cannabis in a fraction of the time of rack drying, and it’s clinically proven to retain more terpenes, CBD and THC. It’s just one more way we help our partners dry better, faster.

Go from fresh to dry in just 2 hours

Trusted by cannabis industry leaders worldwide

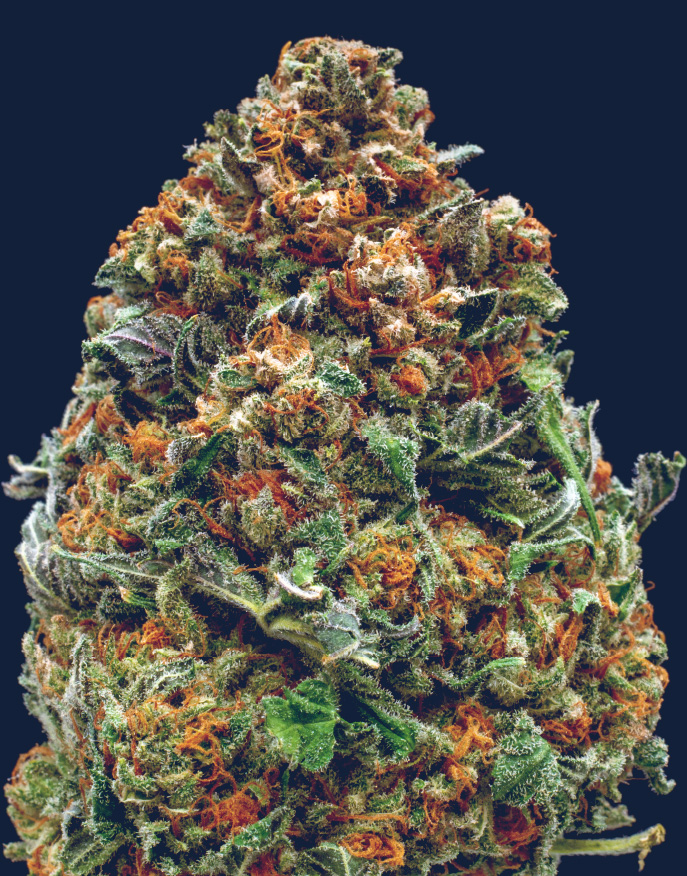

This is a photo of actual REV-dried cannabis.

Here are four reasons why it’s better.

3-log

MICROBIAL

REDUCTION

CONSISTENT, RELIABLE

QUALITY &

REVIEWS

20%

MORE

TERPENES

PRESERVE UP TO

25%

MORE

THC & CBD

*compared to rack drying

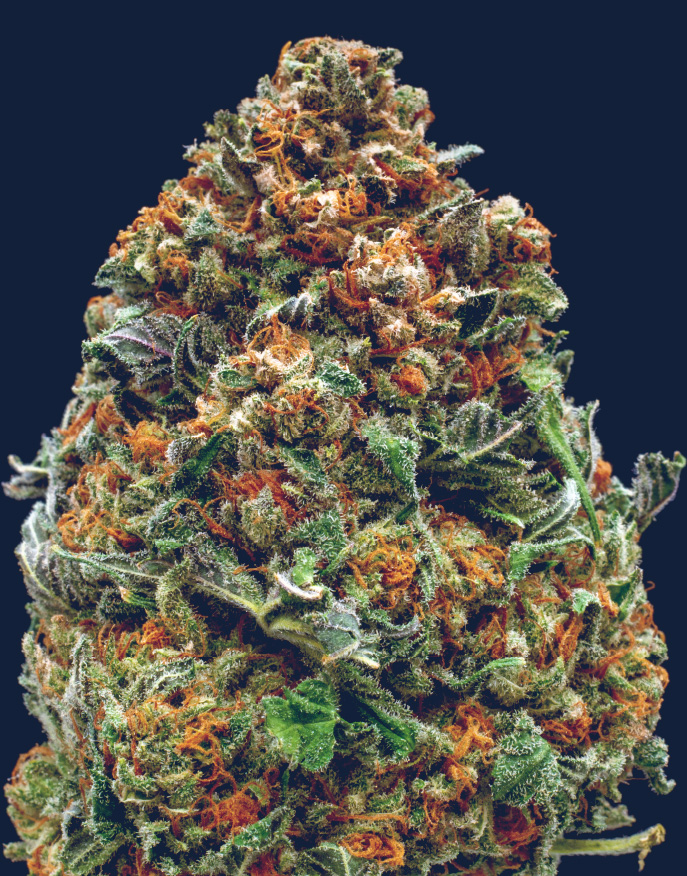

This is a photo of actual REV-dried cannabis.

Here are four reasons why it’s better.

3-log

MICROBIAL

REDUCTION

CONSISTENT, RELIABLE

QUALITY &

REVIEWS

20%

MORE

TERPENES

PRESERVE UP TO

25%

MORE

THC & CBD

*compared to rack drying

Save time, save space, and improve your bottom line.

Lower Costs

- Save on labour costs

- Eliminate costly bottlenecks

- Reclaim valuable floorspace

- Get to market faster

Higher Quality

- Preserve potency

- Improve consistency

- Target precise moisture levels

- 3-Log microbe reduction

- Protect against oxidization

Better numbers across the board

Air Dried

REV™ Dried

Air Dried

Air Dried

REV™ Dried

Featuring two key ways to dry cannabis developed by EnWave’s drying experts.

TerpeneMax

Protocol

UP TO

140

LBS

/HR

(about 63.5kg/hr, wet)

Our TerpeneMax protocol was expertly designed for situations where cannabis taste, smell, appearance and flower quality matters. With a low, uniform heat and precise moisture control, TerpeneMax produces premium quality cannabis will all of the flavor, cannabinoids and flavonoids intact. This protocol is perfect for traditional, smokeable cannabis products.

Rapid Extract

Protocol

OVER

230

LBS

/HR

(about 140kg/hr, wet)

Get the most from your cannabis in record time with our Rapid Extract protocol. Designed with food, drink, topicals, and other cannabis products in mind, EnWave’s Rapid Extract protocol dries cannabis quickly and consistently. It’s the perfect choice for power producers.

Design Your Own Protocol

EnWave’s REV™ drying machines give you precise control over your drying process.

Have an idea for a new product? Want to get the most from a particular strain? Work directly with our team of drying experts to find the exact settings that best meet the needs of your product.