What is REV™?

EnWave’s REV™ technology isn’t just another drying method—it’s a breakthrough that’s redefining quality, efficiency, and sustainability in food manufacturing. The magic lies in its unique approach: a carefully controlled vacuum lowers water’s boiling point, while microwave energy provides uniform, rapid moisture removal. This means food producers can now create shelf-stable products that retain their original color, taste, and nutritional value. Let’s dive into the details of REV™ technology and explore how it’s transforming the food industry.

Understanding REV™ Technology

REV™, which stands for Radiant Energy Vacuum, is EnWave’s patented process that uses vacuum microwave drying to dehydrate food and plants more efficiently and with higher quality than traditional methods. This unique combination of vacuum and microwave energy results in a fast, gentle drying process that can be precisely controlled to achieve optimal results for a wide range of products.

The Vacuum Advantage

The vacuum component of REV™ technology offers several key benefits:

- Lower boiling point; By reducing atmospheric pressure, the vacuum lowers the boiling point of water, enabling fast, low-temperature processing.

- Rapid water removal: This low-temperature environment allows for quick dehydration without cooking or oxidizing the product.

- Closed system: The vacuum chamber captures volatilized components, preserving flavors and aromas.

- Product “puffing”: The vacuum environment can create a pleasing puffed texture in certain products.

The Microwave Advantage

Microwave energy complements the vacuum process by providing:

- REV™ technology achieves 85-90% efficiency, significantly reducing energy requirements compared to traditional drying methods.

- Microwaves heat the product uniformly and rapidly throughout its volume.

- Precise temperature regulation allows for excellent process control and cycle customization.

The Science Behind REV™

EnWave’s REV™ technology achieves low-temperature, accelerated dehydration by applying a vacuum within the main chamber of the machinery to lower the atmospheric pressure, thereby lowering the boiling point of water. A specific amount of microwave energy is then introduced to homogeneously remove moisture at controlled low temperatures where the vapor pressure equals the atmospheric pressure created.

This combination of vacuum and microwave energy results in a unique drying process that offers several advantages over conventional methods:

Rapid drying

REV™ technology can dry products in 30-60 minutes, compared to hours or days required by traditional methods.

Low-temperature processing

The vacuum environment allows for gentle drying that preserves heat-sensitive compounds.

Uniform drying

Microwave energy provides volumetric heating, ensuring even moisture removal throughout the product.

Quality retention

The rapid, low-temperature process helps preserve nutritional value, taste, color, and texture of food products.

Watch the clip below to see the technology in action!

Safety of REV™ Technology

EnWave’s REV™ technology is not only effective but also safe for food processing:

- Non-ionizing radiation: The microwave frequency used is lower than natural light, ensuring it only produces a thermal effect on foods.

- WHO approved: The World Health Organization has declared microwave processing “a safe form of food processing.”

- Widespread acceptance: Over 90% of US households regularly use microwave ovens, demonstrating the technology’s safety and acceptance.

- Multiple safety features: REV™ dryers incorporate numerous redundancies to prevent microwave leakage.

Throughput and Efficiency

REV™ machines are designed for optimal efficiency and throughput:

- Water removal capacity: REV™ machines can remove about 0.8-1kg of water per kW per hour.

- Customizable power: The kW used depends on product load and cycle time, allowing for tailored processing.

- Loading density optimization: Each section of the machine can generate 10kW of microwave power, typically using 1-2kW per kg of product per section.

- Cycle time flexibility: Minimum cycle times range from 1.5 minutes for quick runs to 3 minutes for normal runs.

Applications and Benefits

REV™ technology has found applications across various food categories:

Fruits and vegetables

Produces shelf-stable products that retain original flavor profiles and nutrients.

Dairy products

Effectively dries cheese, yogurt, and other dairy items. If you need a bit of inspiration our partner, Moon Cheese, is doing amazing and just launched their space spice product line, go check it!

Meats and seafood

Preserves protein-rich foods while maintaining quality. Read about our Icelandic partner, Næra® and their rich fish snacks!

Snack foods

Creates innovative, healthy snack options with extended shelf life.

Ingredients

Produces high-quality dried ingredients for various food applications.

The versatility of REV™ technology opens up new possibilities for product innovation and market expansion.

Scaling with Your Business

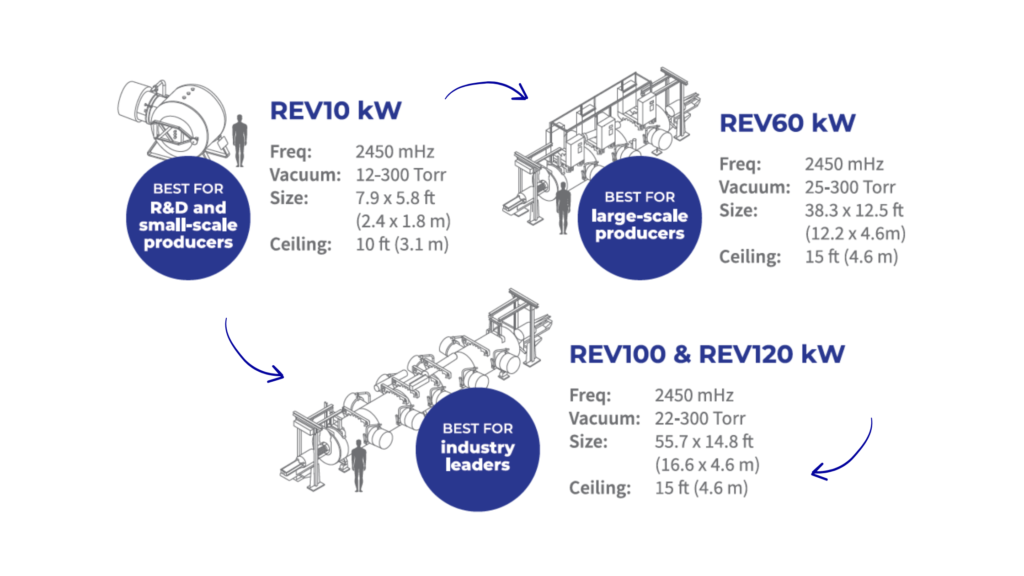

EnWave offers a range of REV™ machines to suit different production scales:

- REV™ 10kW: Ideal for R&D and small-scale producers.

- REV™ 60kW: Suitable for large-scale producers.

- REV™ 100kW and 120kW: Designed for industry leaders with high-volume production needs.

This scalability allows businesses to start small and expand their REV™ capacity as demand grows.

Sustainability and Cost-Effectiveness

REV™ technology offers significant advantages in terms of sustainability and operational costs:

- Energy efficiency: The process is more energy-efficient than freeze-drying and air drying.

- Reduced processing time: REV™ drying is significantly faster than traditional methods, increasing productivity.

- Space savings: REV™ machines require up to 30% less space than traditional drying equipment.

- Extended shelf life: REV™-dried products have a longer shelf life, reducing food waste.

- Lower transportation costs: The reduced weight of dried products leads to savings in shipping.

EnWave’s REV™ technology represents a significant leap forward in food dehydration. By combining the benefits of vacuum and microwave drying, REV™ offers a faster, more efficient, and higher-quality alternative to traditional drying methods. As the food industry continues to evolve, REV™ technology is poised to play a crucial role in meeting the growing demand for high-quality, sustainable food products.

Are you ready to revolutionize your food production process? Discover how EnWave’s REV™ technology can transform your business. Contact us today for a consultation and see the power of REV™ in action. Let’s create the future of food together!