The evolution of food dehydration across cultures

For thousands of years, food dehydration has played a critical role in preserving and extending the shelf life of food. Across cultures and continents, ancient civilizations developed their own methods to dry fruits, vegetables, meat, and herbs; techniques that sustained communities during lean times and enabled the transport of food over long distances. Fast forward to today, and food dehydration has evolved significantly, driven by technological advances that make the process faster, more efficient, and more sustainable. This journey from sun-dried foods to revolutionary microwave-assisted dehydration highlights both cultural ingenuity and modern innovation, with Enwave’s patented Radiant Energy Vacuum (REV™) technology leading the way in reshaping the future of food dehydration.

A global history of food preservation

Long before electricity and modern machinery, ancient societies relied on simple yet effective methods of food dehydration. By removing moisture, they prevented spoilage, preserved nutrients, and created portable, long-lasting food. Let’s take a look at how different cultures approached dehydration throughout history:

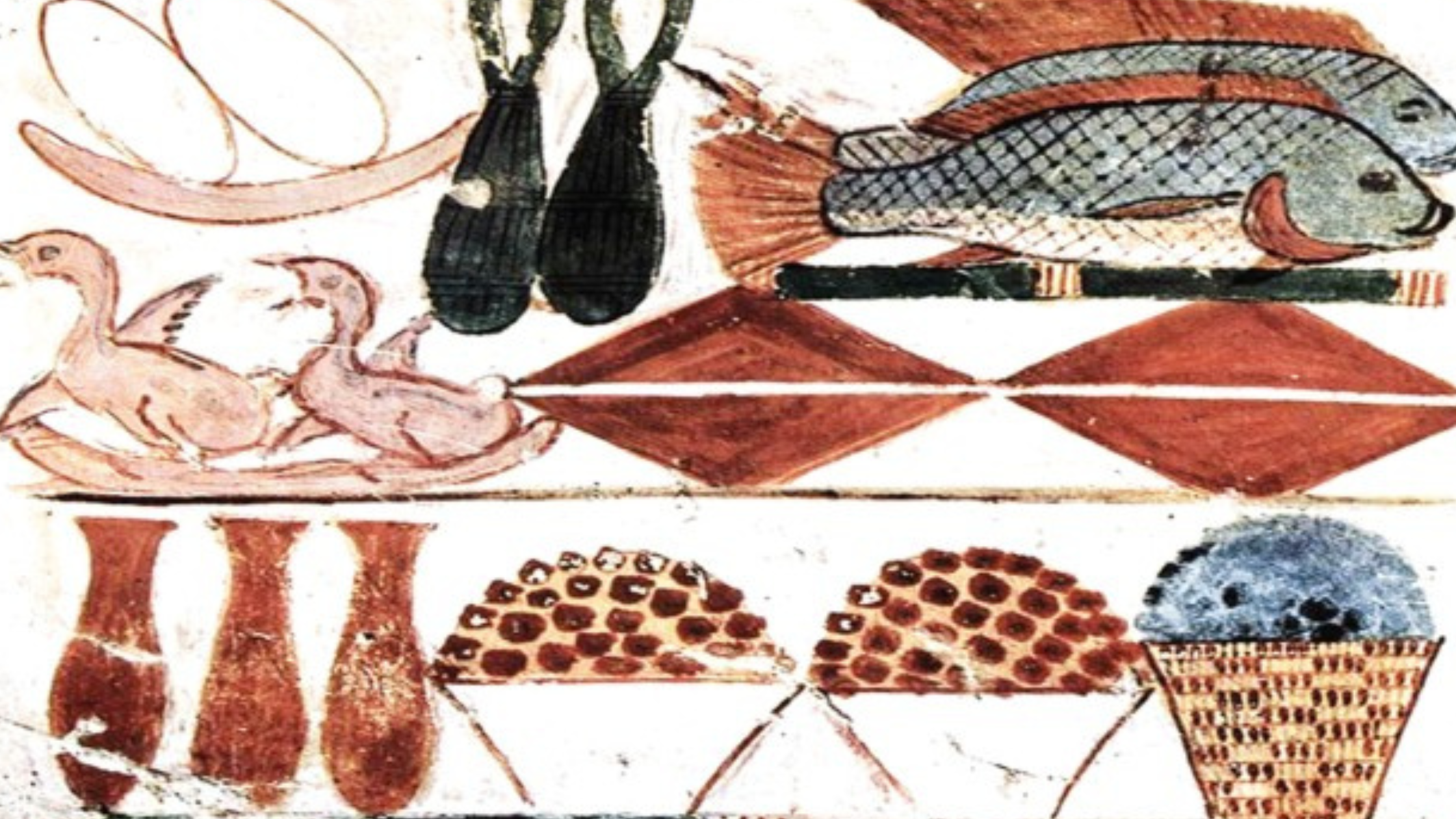

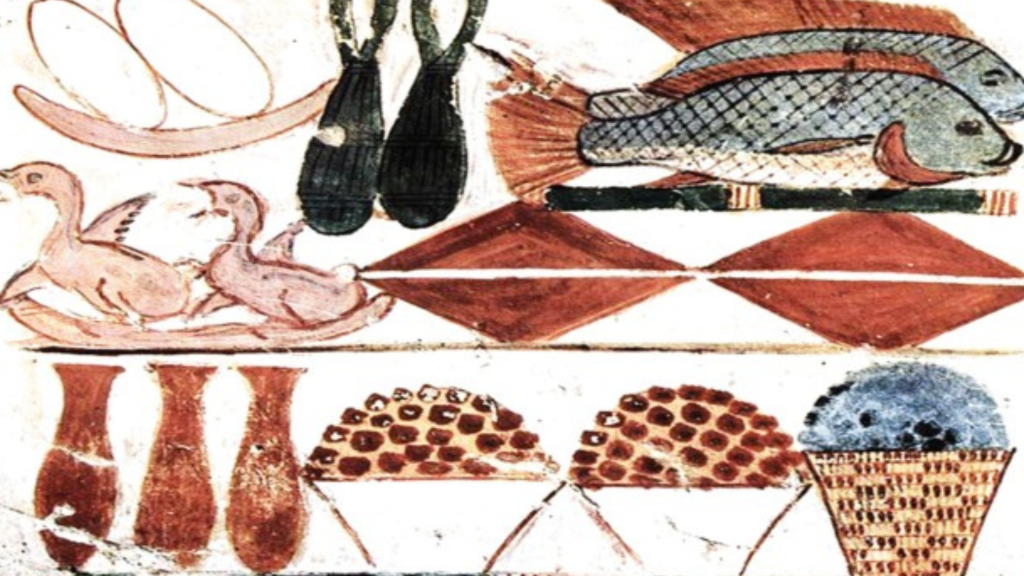

Ancient Egypt and the Mediterranean

Archaeological evidence shows that Egyptians dried fish and grains in the desert heat as early as 12,000 years ago. Grapes were sun-dried to make raisins, and figs and dates were commonly preserved to provide sustenance during long journeys.

Indigenous North American Tribes

Native peoples, such as the Hopi and Navajo, mastered air-drying meat and berries. Pemmican, a high-energy food made from dried meat, fat, and berries, was a vital source of nutrition during hunting expeditions and harsh winters.

China and East Asia

In China, drying tea leaves, mushrooms, and seaweed became widespread practices. Bamboo trays were used to dry foods under the sun, and later, early forms of ovens were developed for faster dehydration.

South America

The Andean peoples, including the Incas, developed chuño, a freeze-dried potato product. By exposing potatoes to the freezing temperatures of the Andes at night and sun-drying them by day, they created a food with a shelf life that could last for years.

While these traditional techniques served communities well for centuries, they were often labor-intensive, slow, and dependent on weather conditions. Over time, scientific advancements laid the groundwork for modern dehydration methods that offered greater control, consistency, and scalability.

The industrial era

The Industrial Revolution marked a turning point in food preservation. As urban populations grew and food distribution expanded, new technologies were developed to meet the demand for longer-lasting, shelf-stable foods.

- Freeze Drying: Originally developed in the 20th century to preserve pharmaceuticals, freeze-drying quickly gained popularity in the food industry. By freezing food and then reducing the surrounding pressure to remove moisture through sublimation, freeze-drying produced lightweight, nutrient-rich foods ideal for military rations, space travel, and emergency supplies. However, freeze-drying can be energy-intensive and time-consuming, often requiring specialized commercial freeze-dry machines.

- Spray Drying: Used primarily for liquids like milk and coffee, spray drying involves spraying a fine mist of liquid into a hot air chamber, where moisture rapidly evaporates, leaving behind a dry powder. This method is efficient but less suitable for whole foods or snacks.

REV™ Technology: The next generation of dehydration

While freeze-drying and spray-drying represented major leaps forward, they are not without limitations. That’s where Enwave’s REV™ technology comes in, a groundbreaking microwave-assisted vacuum dehydration process that addresses the challenges of traditional drying methods and sets a new standard for efficiency, quality, and sustainability.

Unlike freeze-drying, which can take many hours, REV™ technology dramatically reduces drying time while preserving the flavor, color, and nutrients of the original product. By applying controlled microwave energy under vacuum conditions, moisture evaporates quickly and evenly at low temperatures, minimizing thermal damage. This process offers several key advantages:

- Enhanced Efficiency: REV™ technology can dry products up to several times faster than freeze-drying, reducing production bottlenecks and energy consumption.

- Superior Quality: Unlike hot air drying, which can cause shrinkage and nutrient loss, REV™ technology preserves the natural texture, taste, and nutritional profile of foods.

- Sustainability: Faster drying times mean lower energy usage, making REV™ a more environmentally friendly option compared to conventional methods.

Revolutionizing food innovation

Enwave’s REV™ technology is already making waves in the food industry, supporting product development across a range of applications, from dried fruit snacks to dairy products and plant-based proteins. Here are just a few examples of how REV™ is driving food innovation:

- Dried Fruit and Vegetable Snacks: With consumers increasingly seeking healthy, minimally processed snacks, REV™ technology allows producers to create crispy, flavorful dried fruits and vegetables without the need for added sugars or preservatives.

- Dairy and Plant-Based Ingredients: REV™ enables the gentle dehydration of dairy products like yogurt and cheese, as well as plant-based alternatives, to create shelf-stable, high-protein snacks.

- Functional Foods: By preserving the bioactive compounds in ingredients like mushrooms, herbs, and berries, REV™ technology supports the growing market for functional foods that offer health benefits beyond basic nutrition.

The future of dehydration

As the global demand for shelf-stable, high-quality foods continues to grow, the need for sustainable, efficient drying methods has never been greater. Enwave’s REV™ technology represents the future of food dehydration, offering a scalable solution that meets the needs of food processors, manufacturers, and consumers alike.

By building on the rich history of food preservation and leveraging cutting-edge technology, Enwave is not only transforming the way food is dried but also helping to create a more sustainable and resilient food system.

For more information about Enwave’s REV™ technology and its applications, contact us and explore how microwave drying equipment is shaping the future of food dehydration.

Sources:

- Institute of Food Technologists (IFT): Food Processing Overview

- National Center for Home Food Preservation: Historical Origins of Food Preservation

By blending ancient wisdom with modern technology, Enwave is leading the charge in redefining what’s possible in food dehydration, delivering better quality, improved efficiency, and a more sustainable future for all.