How does the freeze-drying process work?

Freeze-drying, also known as lyophilization, has long been a staple in food processing, pharmaceuticals, and product innovation. However, as demand grows for nutrient-rich, shelf-stable foods, new technologies like microwave dehydration are redefining what’s possible. Let’s understand how freeze-drying works, where it falls short, and why advanced microwave drying technologies like EnWave’s Radiant Energy Vacuum (REV™) are emerging as a better solution for commercial and industrial applications.

What is lyophilization?

Lyophilization, or freeze-drying, is a dehydration process that removes water from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through the liquid phase, a process known as sublimation. This method is widely used for preserving foods, pharmaceuticals, and biological materials, thanks to its ability to maintain the shape, color, and nutritional value of the original material.

The science behind freeze-drying

The freeze-drying process unfolds in three primary stages:

1. Freezing

The product is first frozen, typically under atmospheric pressure. This step is crucial because the formation of ice crystals impacts how easily water can be removed in later stages. The freezing must be rapid and uniform to avoid concentration gradients and ensure consistent product quality.

2. Primary Drying (Sublimation)

Once frozen, the product is subjected to a vacuum. Under these low-pressure conditions, heat is gently applied, causing the ice within the product to sublimate, turning directly from solid to vapor. This step removes the majority of water content, leaving behind a porous structure that can be easily rehydrated.

3. Secondary Drying (Desorption)

After most of the ice has been sublimated, the product still contains bound water. Secondary drying involves raising the temperature slightly (while maintaining the vacuum) to drive off this remaining moisture, achieving the desired final humidity for storage and shelf stability.

The result is a lightweight, shelf-stable product that retains much of its original structure, flavor, and nutrients, making freeze-drying a preferred method for products like dried fruit snacks, instant coffee, and emergency rations.

The downside of freeze-drying

Though lyophilization excels at preserving texture, studies show it struggles to retain heat-sensitive bioactive compounds like vitamin C and antioxidants, which degrade during extended processing. For manufacturers, the high operational costs stemming from energy use and lengthy cycle times make scalability a challenge.

High Energy Consumption

Freeze-drying is an energy-intensive process. Maintaining extremely low temperatures and vacuum conditions over long periods requires substantial electricity, making it one of the most energy-demanding forms of commercial food drying. This translates to higher operational costs and a larger carbon footprint, which is increasingly at odds with sustainability goals in food processing and manufacturing.

Expensive Equipment and Operations

Commercial freeze dry machines and industrial freeze dryers are costly to purchase, operate, and maintain. The initial investment can be prohibitive for small businesses or those looking to scale quickly, while ongoing maintenance adds to long-term costs.

Time-Consuming Process

Freeze-drying is not fast. It can take anywhere from several hours to multiple days to complete a single batch, slowing down production lines and limiting throughput for commercial food drying and product development. In industries where speed and flexibility are essential, this can be a major bottleneck.

Inconsistent Preservation of Bioactive Compounds

While freeze-drying is effective at retaining many nutrients, it often falls short when it comes to preserving sensitive bioactive compounds, such as antioxidants, polyphenols, and other phytochemicals that are increasingly valued in functional foods and nutraceuticals. Extended processing times and exposure to varying temperatures can degrade these compounds, reducing the health benefits of the final product.

Texture and Flavor Changes

Freeze-dried foods can sometimes suffer from altered texture and flavor profiles. The porous structure, while great for rehydration, can make certain foods brittle or chalky, and subtle flavors may be lost during the process.

What’s next?

EnWave’s Radiant Energy Vacuum (REV™) dehydration merges vacuum pressure with targeted microwave energy to remove moisture faster than freeze-drying. By maintaining temperatures below 40°C (104°F), it preserves delicate nutrients and flavors that older methods sacrifice:

- Bioactive compounds like polyphenols remain intact due to shorter exposure times.

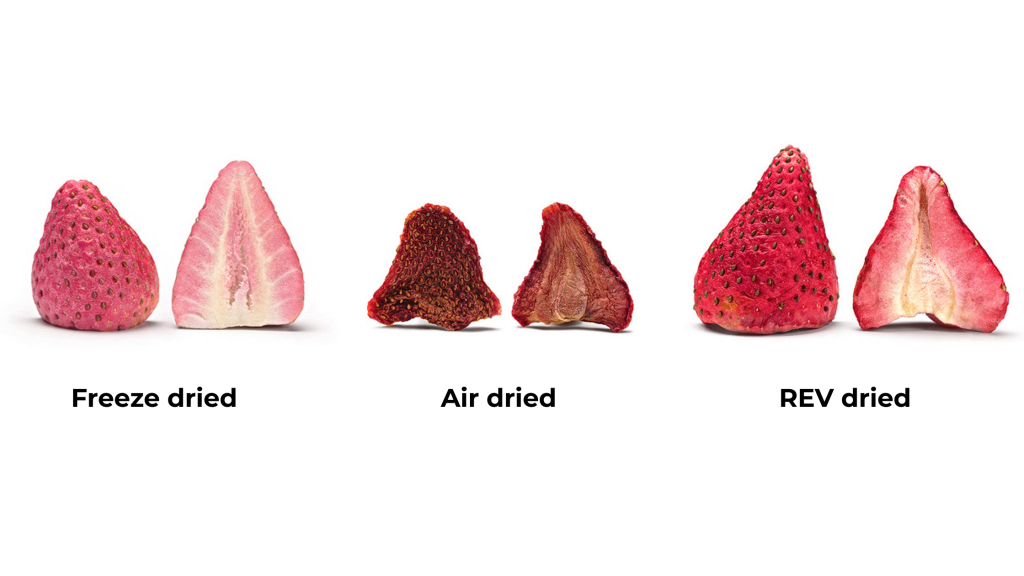

- Sensory appeal is enhanced REV-dried strawberries retain their bright color and chewy texture, unlike leathery freeze-dried versions.

- Sustainability gains come from reduced energy use and smaller facility footprints.

Why Modern Food Innovators Choose REV™

From Dole’s crispy fruit snacks to the U.S. Army’s shelf-stable cheesecake bars, REV™ is enabling products that were once impossible. Its speed allows smaller batches for R&D, making it ideal for:

- Product development teams testing novel ingredients.

- Manufacturers transitioning from batch to continuous drying.

- Brands prioritizing clean-label, nutrient-dense positioning.

As consumers demand transparency and sustainability, technologies like REV™ are becoming essential. Unlike methods tied to ancient climates or 20th-century compromises, microwave dehydration offers a third path, one that honors food’s nutritional integrity while meeting modern efficiency standards.

Ready to Transform Your Drying Process?

EnWave partners with leading brands to reimagine what’s possible in food preservation. Whether you’re developing the next generation of snacks or optimizing your production line, our team provides the tools and expertise to dry smarter.

Further reading

Nowak D, Jakubczyk E. The Freeze-Drying of Foods-The Characteristic of the Process Course and the Effect of Its Parameters on the Physical Properties of Food Materials. Foods. 2020 Oct 18;9(10):1488. doi: 10.3390/foods9101488. PMID: 33080983; PMCID: PMC7603155.