What’s the best way to preserve nutrition in snacks?

Fruits and vegetables are some of the most nutrient-dense foods in the human diet. But when they’re processed and preserved without care, they often lose the very compounds that make them valuable. Recent peer-reviewed research and sensory testing confirm that microwave drying doesn’t just match traditional options, it can often exceed them in preserving nutrition, appearance, flavor, and energy efficiency. For food processors and brands focused on product development, food innovation, and long-term market growth, this evolution in drying technology offers an unmatched opportunity to build better food from the ground up.

Comparing drying methods side-by-side

A recent study published by the UBC Faculty of Land and Food Systems compared air drying, freeze drying, and REV™ vacuum microwave drying using broccoli, carrots, and oranges. The researchers examined how nutrition, sensory quality, and shelf life vary across these commercial drying technologies. The results are striking.

Broccoli and vitamin C retention

- REV™ drying preserved around 95.4% of the original vitamin C

- Air drying preserved just 33.6%

- Freeze drying, while better than air drying, still showed material degradation under longer processes

Carrots and β-carotene stability

- REV™ preserved about 57.5% of β-carotene

- Air drying left less than 17.1%

- Bright color remained mostly intact with REV™—a key advantage for fresh-looking snacks

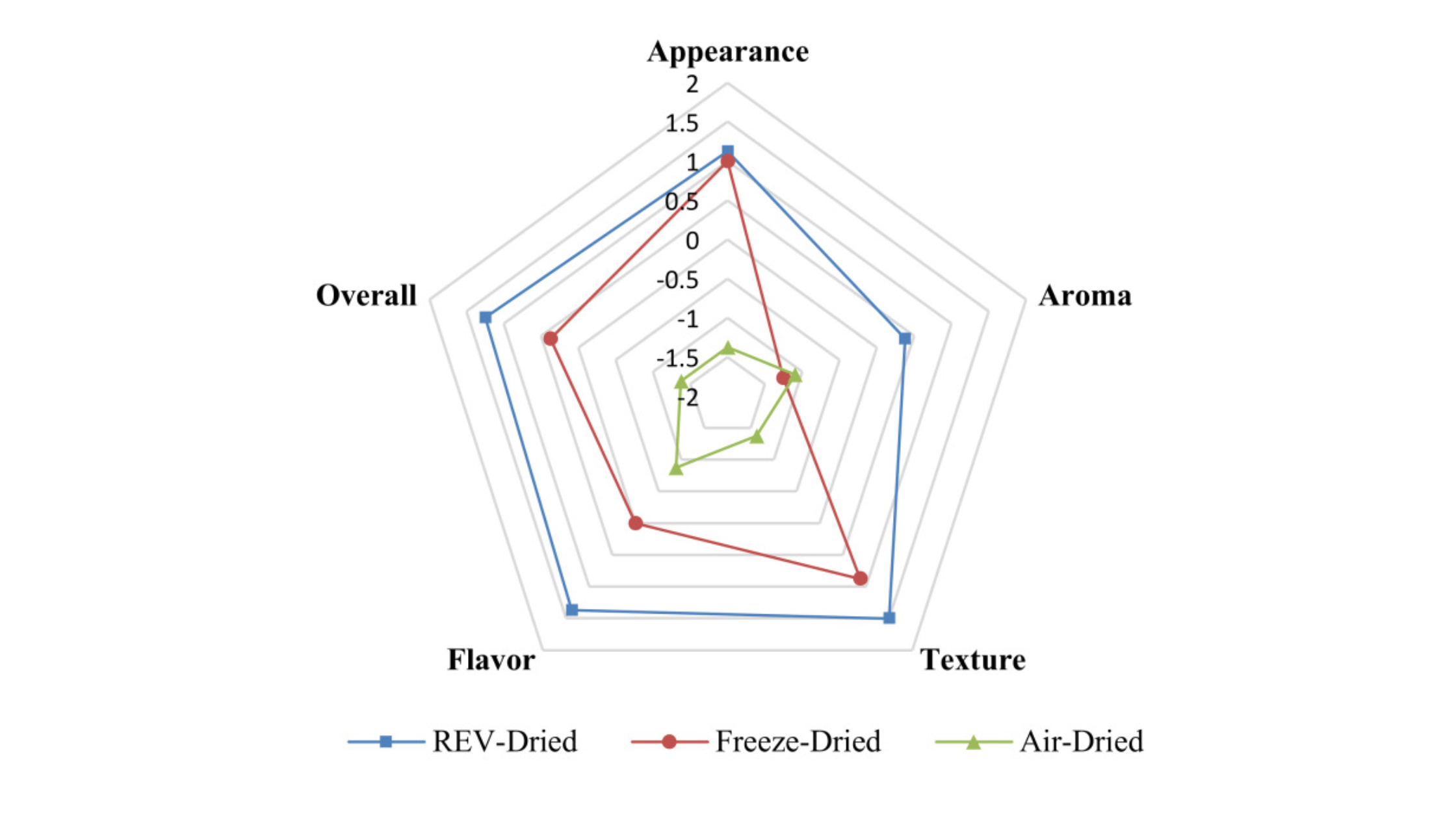

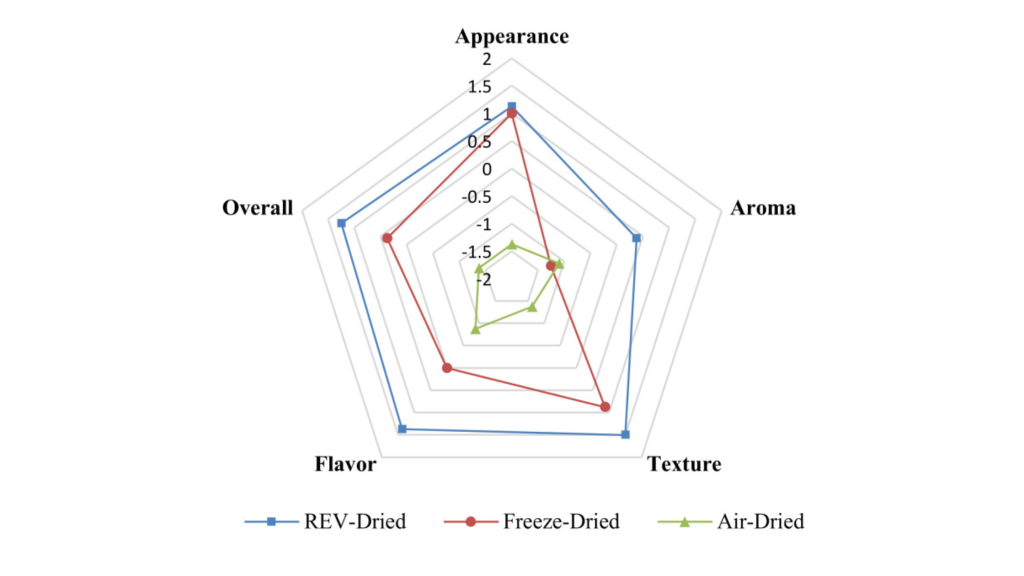

Oranges and sensory quality

- REV™ processed samples performed highest in taste, aroma, appearance, and texture

- Air-dried samples were darker, less flavorful, and had tough or rubbery textures

- Freeze-dried oranges scored well in appearance, but not in flavor depth or mouthfeel

Across categories, REV™ enabled better preservation of sensitive nutrients, visual appeal, and palatability; three critical dimensions when building modern, consumer-facing snack products that deliver on both health and indulgence.

Efficiency that drives growth

Drying plays a central role in shaping energy consumption, production capacity, shelf life, and even how products are packaged down the line. Traditional commercial freeze drying technology, while effective at preservation, is slow and expensive. A single batch can take anywhere from 24 to 72 hours, and the energy demand is costly, especially at industrial scale.

By contrast, EnWave’s patented REV™ microwave drying equipment handles comparable loads in a fraction of the time, often between 30 to 90 minutes depending on the product and moisture content. This allows for:

- Real-time responsiveness during harvest season

- Better use of labor and production lines

- Reduced spoilage risks

- Shorter lead times for buyers and co-packers

Manufacturers aiming for sustainability and profitability can no longer afford to rely on drying cycles that monopolize power, workforce hours, and floor space. Increasingly, industry partners are shifting to REV™ to reduce energy costs and production bottlenecks, without compromising product quality.

Why Nutrient Retention Really Matters

For the consumer, nutrient data goes deeper than lab results. It shapes brand identity, marketing claims, and consumer trust. Retailers and ingredient-aware consumers are looking for snacks that truly deliver on nutrition.

As the global functional food sector continues to grow with major segments like plant-based protein, digestive health snacks, and clean-label nutrition reaching new audiences; REV™ stands out for its ability to retain:

- Vitamin C and heat-sensitive antioxidants

- Colorful phytochemicals like betalains and flavonoids

- Natural sweetness and flavor compounds

- Whole-ingredient integrity for raw or semi-processed textures

Because vacuum microwave drying occurs at lower temperatures and under reduced oxygen pressure, nutrients aren’t lost, they’re stabilized. And because the drying is uniform from the inside out, the final product can be designed to maintain its structure without needing aggressive processing aids like gums, emulsifiers, or preservatives.

Snacks that look and taste fresh

The food industry is visual. One glance often decides whether a snack hits the cart or stays on the shelf. Whether you’re developing dried fruit snacks, veggie chips, or shelf-stable meal components, product developers today can’t afford to compromise on:

- Color retention: REV™ preserves vibrant and natural hues that stand out next to pale or oxidized counterparts

- Texture range: From crisp to chewy, thanks to controlled moisture content and uniform dehydration

- Aroma release: Near-fresh fragrance cues that signal quality and real ingredient usage

- Taste fidelity: Clean fruit, herb, or vegetal notes rather than “cooked” or bitter finishes

Consumer testing has consistently shown that sensory appeal (taste, appearance, and mouthfeel) drives product loyalty more than micronutrient counts on the label. This is where REV™ truly differentiates your food innovation program from offerings produced in industrial freeze dryers or conventional air-drying machines.

Application versatility

Microwave vacuum dehydration has become a versatile solution, with applications ranging from snacks and powders to supplements and specialty ingredients including:

- Powders for supplements, drink mixes, and culinary seasonings

- Inclusions in cereals, processed foods, and bars

- Clean-label applications for school feeding programs

- Plant-based proteins with sensitive flavor/texture profiles

- Functional snacks rich in probiotics, polyphenols, or mushrooms

For companies planning new product innovations or looking to extend shelf life without adding synthetic preservatives, microwave-based drying is a superior solution that delivers shelf stability without compromising nutrition.

Doing more with less

There’s no question that energy, emissions, and environmental impact are key areas of focus today. According to a comparative report, vacuum microwave dehydration consumes up to 80–90% less energy than traditional freeze drying. That matters when electricity prices rise, or when carbon tracking becomes part of compliance.

Other benefits include:

- Compact footprint: REV™ machines require significantly less floor space than an equivalent-volume freeze dryer

- No cryogens or pre-freezing steps: Reduces resource and equipment load

- Fewer packaging requirements: Resulting textures often require less oxygen-barrier packaging than freeze-dried equivalents

For brands, sustainability is also narrative: less energy, faster production and lower emissions. All read well to retailers intent on hitting ESG goals. For manufacturers, it’s faster time to ROI, less downtime, and a smaller environmental, but also fiscal, footprint.

What EnWave offers product developers

When you work with EnWave, you join a community of food innovators rethinking the way dried products bring nutrition and excitement to the shelf.

Whether you’re creating your first plant-based snack or looking to transition away from slow commercial freeze drying systems, EnWave provides:

- Custom REV™ systems to match your product line from pilot to production

- Research support via REVworx™, EnWave’s certified toll dehydration service for trial runs and contract manufacturing

- Expert guidance on formulation, texture targeting, and moisture control

- Facility design and engineering partnerships to future-proof your operation

No matter your starting point, we help food companies dry better, faster.

Get started with REV™

Modern food innovation needs drying systems designed for today’s demands: speed, nutrition, energy efficiency, and zero compromise on quality.

If you’re exploring alternatives to industrial freeze dryers or evaluating how to improve your food dehydration process, it’s time to talk to EnWave.

We’ll help you preserve not just food, but what makes it exceptional.

Visit enwave.net to learn how. Want to start small? Explore toll drying at REVworx™.