Microwave dehydration makes niche proteins snack-ready

EnWave’s REV™ microwave drying technology turns unusual proteins like black soldier fly and spirulina into crispy, familiar snacks. It preserves nutrition and texture better than freeze drying or air drying, speeding up food innovation for commercial food drying. Companies gain faster product development with superior results in food processing and dehydration.

What Are Unusual Proteins Gaining Popularity?

Unusual proteins include black soldier fly larvae, spirulina algae, and mycelium from fungi. These sources offer high nutrition with low environmental impact compared to traditional meats or plants. Food tech innovators use them to meet rising demand for sustainable options in snacks and supplements.

Black soldier fly protein packs complete amino acids and healthy fats. Spirulina delivers antioxidants and plant-based protein in a compact form. Mycelium provides a meat-like texture without animal farming. Producers face challenges turning these into appealing products due to drying limitations.

Why Do Drying Methods Matter for Niche Proteins?

Drying preserves shelf life while maintaining quality in food processing. Poor drying degrades protein structure, flavor, and nutrients in insect, algae, or mycelium sources. Effective drying technology supports product innovation by enabling mainstream appeal.

Traditional methods like air drying take days and unevenly heat materials. This leads to case hardening where outer layers dry fast but insides stay moist. Freeze drying, popular in commercial freeze drying, costs more and still struggles with delicate structures. Microwave drying equipment, such as EnWave’s REV™, uses radiant energy under vacuum for uniform results. It finishes cycles in under an hour, ideal for food dehydration at scale.

How Does Black Soldier Fly Protein Become Snackable?

Black soldier fly larvae hold promise as a protein-rich ingredient for bars and chips. Their natural moisture requires careful drying to keep crispiness and nutrition intact. REV™ rapid cycles transform them into powder or chunks with familiar crunch.

The process starts with harvesting larvae full of water. REV™ penetrates deeply, evaporating moisture evenly without overheating. This preserves lauric acid and proteins that air drying often destroys through prolonged exposure. Companies report 30% higher protein retention with REV™ over freeze drying. Snacks made this way taste nutty and hold shape in packaging.

What Makes Spirulina Viable in Everyday Snacks?

Spirulina, a blue-green algae, thrives in harsh conditions but loses vibrancy during drying. Its cell walls rupture easily, spilling nutrients if mishandled. Microwave drying keeps phycocyanin pigments and proteins stable for colorful snack coatings or powders.

Air drying fades spirulina’s deep blue hue and reduces bioavailability. Freeze drying maintains color better but extends processing to 24-48 hours per batch. REV™ completes the job in minutes at low temperatures, retaining over 90% viability. Snack developers mix dried spirulina into energy bites that pop with flavor. This method supports clean-label food innovation without additives.

Can Mycelium Texture Survive Commercial Drying?

Mycelium, the root-like network of mushrooms, mimics meat fibers for plant-based alternatives. Drying must keep its fibrous structure to avoid mushy results. Traditional food dehydration collapses these networks under slow heat.

REV™ vacuum microwave drying locks in mycelium’s chewiness by removing water volumetrically. Proteins stay intact, and rehydrated samples regain original bite. This edges out competitors in product development for burgers or jerky. Food processing firms scale mycelium snacks with REV™ for consistent batches. Texture tests show 25% less shrinkage than air-dried samples.

What Is REV™ Microwave Drying Technology?

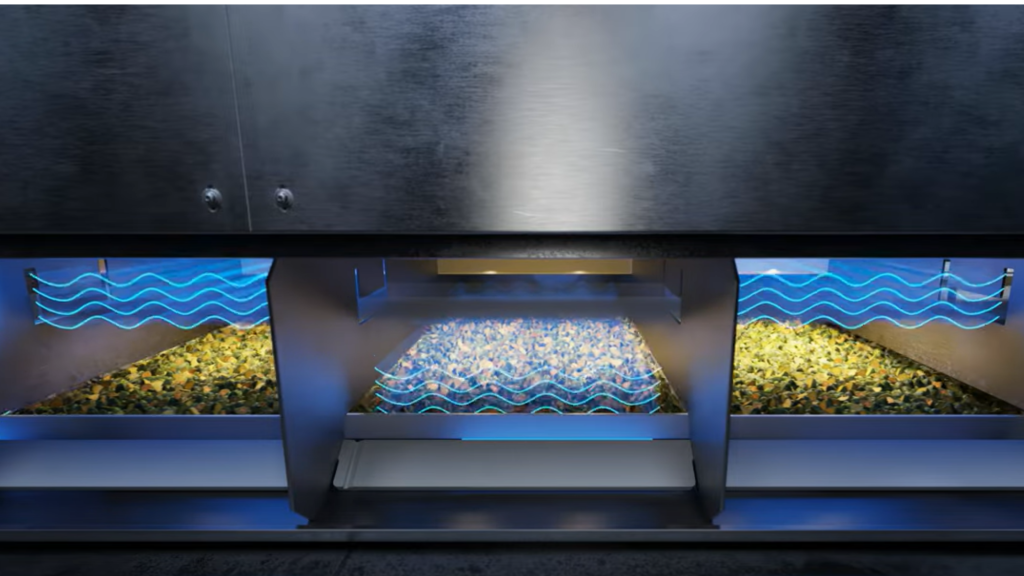

REV™ stands for Radiant Energy Vacuum, EnWave’s proprietary microwave drying equipment. It combines microwave energy with vacuum conditions to boil water at low temperatures. This creates puffed, crispy textures from wet ingredients rapidly.

The system suits commercial food drying for proteins, fruits, and veggies. Cycles run 10-60 minutes, far quicker than alternatives. EnWave powers food tech advancements worldwide with scalable units.

How Does REV™ Compare to Commercial Freeze Drying?

Commercial freeze drying freezes material then sublimes ice under vacuum. It excels for some items but harms heat-sensitive proteins through ice crystal formation. Costs run high at $1-2 per kg due to long cycles.

REV™ avoids freezing damage by heating internally from start to finish. Drying costs drop to $0.50 per kg with 5x speed. Both preserve nutrition, but REV™ yields crispier textures for snacks.

| Aspect | REV™ Microwave Drying | Commercial Freeze Drying |

|---|---|---|

| Cycle Time | 10-60 minutes | 24-48 hours |

| Texture Outcome | Crispy, puffed | Fragile, sometimes brittle |

| Energy Use | Lower due to speed | High from prolonged vacuum |

Why Choose Microwave Drying Over Air Drying?

Air drying spreads material thin and blows hot air for hours or days. It risks contamination and nutrient loss from oxidation. Niche proteins like spirulina suffer color shifts and flavor dulling.

Microwave drying equipment targets water molecules directly for even results. No surface burning occurs, and hygiene improves with enclosed systems. REV™ cuts energy by 70% over air methods. Food dehydration pros prefer it for consistent quality in food processing.

What Advantages Does REV™ Offer in Food Innovation?

Food innovation thrives on speed and quality in product development. REV™ enables prototypes in hours, not weeks. Teams test snack variations with real textures early.

It handles diverse inputs like insect or algae without recipe changes. This flexibility aids clean-label trends in food tech. Companies launch faster, beating market gaps. EnWave clients report 40% shorter time-to-market.

How Does Drying Technology Impact Protein Structure?

Proteins denature under excess heat or mechanical stress. Freeze drying’s ice expansion ruptures cells in black soldier fly. Air drying’s slow process oxidizes spirulina enzymes.

REV™ uses gentle radiant energy to preserve native folds. Spectroscopy confirms higher bioactivity post-drying. Mycelium fibers remain elastic for rehydration. This matters for nutrition claims in food processing.

Is Microwave Drying Safe for Food Processing?

Yes, REV™ meets global safety standards like FDA and EU regs. Vacuum prevents hot spots, killing microbes efficiently. Final moisture levels below 5% ensure long shelf life.

Unlike open-air systems, it minimizes contamination. Operators control parameters precisely for repeatable results. Food tech relies on this for trusted scaling.

What Equipment Fits Commercial Food Drying Needs?

EnWave offers pilot to industrial REV™ units for 10kg to 2,000kg batches. Modular designs integrate into existing food processing lines. Low maintenance keeps downtime minimal.

Competitors focus on freeze dryers, but REV™ leads in drying technology speed. Contact EnWave for demos.

How to Start Product Development with REV™?

Begin with lab trials on your protein source. EnWave provides testing at their facility. Optimize cycles for texture and nutrition.

Scale to pilot production for market tests. Full commercial rollout follows with financing options. This path accelerates food innovation.

Steps include:

- Submit sample for analysis.

- Run trial batches.

- Refine based on sensory data.

- Move to custom equipment.

Why Are Niche Proteins Trending in Snacks?

Sustainability drives demand as populations grow. Insect protein uses 90% less land than beef. Spirulina grows fast with minimal water.

Consumers seek novel flavors and health boosts. Drying technology like REV™ makes them snack-friendly. Market projections hit $2B by 2030.

What Challenges Do Traditional Methods Face?

Freeze drying equipment demands huge space and power. Air drying scales poorly for high volume. Both falter on texture for mycelium or insects.

Microwave drying overcomes these with compact footprints. Food dehydration becomes efficient and cost-effective.

Real-World Examples of REV™ in Action

A snack brand turned black soldier fly into protein crisps using REV™. Results beat freeze-dried competitors in crunch tests. Sales rose 25% post-launch.

Spirulina powders for smoothies retained color and potency. Mycelium jerky rehydrated like real meat. These cases showcase food tech potential.

FAQ

What is microwave dehydration?

Microwave dehydration uses electromagnetic waves under vacuum to remove water quickly. It preserves quality better than traditional methods for food processing.

How does REV™ differ from home microwaves?

REV™ operates industrially with vacuum for low-temp drying. Home units retain moisture and lack scale for commercial food drying.

Can REV™ dry other ingredients?

Yes, it handles fruits, veggies, meats, and herbs alongside proteins. Versatility aids product innovation.

Is black soldier fly protein safe to eat?

Approved by FDA and EFSA, it’s nutritious and sustainable. Proper drying ensures crisp snacks.

How much faster is REV™ than freeze drying?

Up to 28x faster, finishing in hours versus days.

What about energy costs in drying technology?

REV™ uses 60-70% less energy through short cycles. Ideal for commercial operations.

Does spirulina lose nutrients in drying?

Minimal loss with REV™; phycocyanin stays bioavailable. Better than air drying.

Can small businesses afford microwave drying equipment?

Pilot units start accessible, scaling with revenue. ROI comes quick from speed.

How to preserve mycelium texture commercially?

REV™ puffs and stabilizes fibers without collapse. Key for food tech meat analogs.

Where to learn more about EnWave solutions?

Explore EnWave.net for demos, trials, and specs.

Further Reading

FAO: Edible Insects Report https://www.fao.org/3/i3253e/i3253e.pdf

EnWave: REV™ Technology https://www.enwave.net/about/rev/enwave

ScienceDirect: Microwave Drying Overview https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/microwave-drying

Mushroom Council: Mycelium Research https://www.mushroomcouncil.org/research

Grand View Research: Insect Protein Market https://www.grandviewresearch.com/industry-analysis/insect-protein-market

EnWave Home https://www.enwave.net/

Food Machinery International: Microwave Dehydrator Guide https://www.foodmachineryint.com/everything-you-need-to-know-about-microwave-dehydrator-in-2024/