Food drying’s hidden carbon footprint

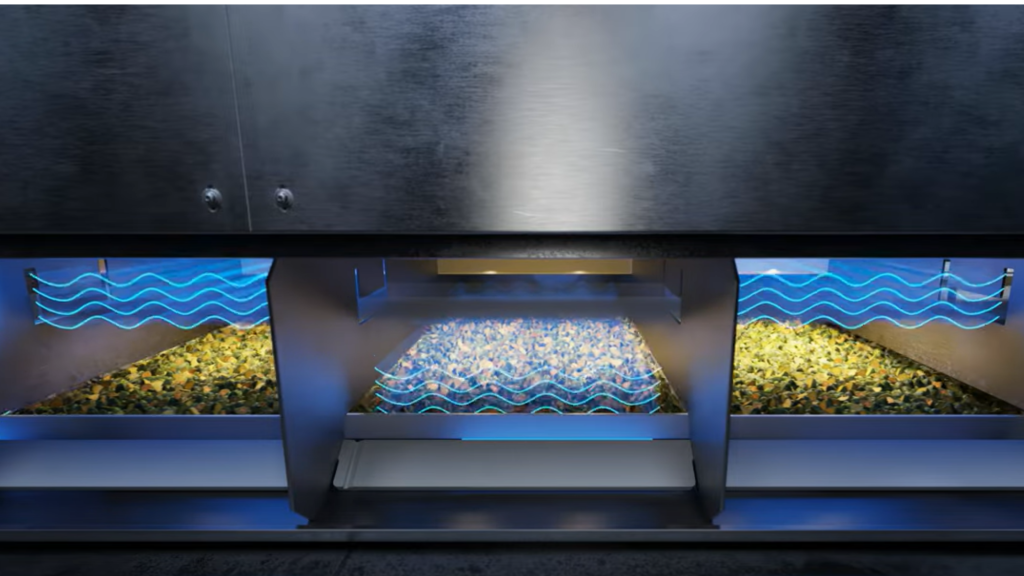

Food drying is a major energy draw in food manufacturing, with traditional methods (especially freeze drying) pushing energy use as high as 5–10 kWh/kg. EnWave’s REV™ microwave vacuum dehydration can cut this by up to 80%, thanks to rapid drying cycles (as fast as 28x compared to freeze drying) and highly efficient, closed-loop technology. This positions REV™ as a leading solution for reducing emissions and meeting tough sustainability and ESG standards.

What is the carbon footprint of food drying processes?

Drying often contributes 15–25% of processing energy in food manufacturing. Most of the environmental burden comes from the heavy energy use for generating heat, managing pressure, and especially powering extended freeze or air drying runs over many hours or days.

- Freeze drying typically has the highest energy demand (5–10 kWh/kg of water removed).

- Air drying averages 2–5 kWh/kg, but requires long hours, resulting in inefficiency and lower product quality.

- Spray drying falls between 4–7 kWh/kg, mainly for powdered foods.

Why does drying have a large environmental impact?

Drying removes the majority of water in foods, often 70–90% of their weight, requiring a massive input of energy. Long run times and inefficient heat transfer in older technologies mean lost energy and high emissions. Freeze drying, for example, can take up to 72 hours for large-scale batches.

How much energy does commercial freeze drying use?

Freeze drying can reach 5–10 kWh/kg of finished product, with roughly 30% of that going to freezing and significant demand from vacuum pumps operating over 1–3 days per batch. This can translate to high energy costs and much larger carbon footprints compared to modern alternatives.

Air and Spray Drying: Still Energy Intensive

- Air drying: While seemingly simple, its 8–24 hour cycles lead to moderate energy demand, lots of food waste, and inconsistent quality.

- Spray drying: Suited to certain food powders and extracts, but still energy-intensive due to the need for constant airflow and hot chambers.

Does freeze drying have a high carbon footprint?

Yes. It’s typically the highest among common methods, with long cycles and refrigeration multiplying total CO₂ emissions per kilogram dried.

How does REV™ reduce the environmental impact?

REV™ runs at about 1–2 kWh/kg, completing drying cycles in under 2 hours and often as quickly as 25x faster than freeze drying. Its vacuum and microwave design means heat targets only water molecules, boosting transfer efficiency to around 85–90%. The closed system also reduces waste and energy losses compared to open-air systems or long-duration freeze dryers.

Sustainability, Water, and Waste

- REV™ preserves nutrition and color with gentler processing, reducing spoilage and food waste.

- Closed-loop engineering means less water and resource waste.

- Smaller plant footprint, up to 30% less space than traditional systems.

ESG and Reporting Advantages

Switching to REV™ for commercial food drying gives brands a clear, measurable drop in energy use, carbon intensity, and operational footprint, supporting ESG reporting and certifications. These savings aren’t hypothetical case studies and on-site data show measurable, quantifiable improvements.

How can REV™ further reduce indirect emissions?

Dried foods are lighter and easier to ship, often reducing downstream fuel use and cold-chain logistics emissions by up to 40–70%. Shelf-stable REV™ output also means less food wasted due to spoilage en route.

Circular Economy & Food Waste

Better control equals fewer rejects. Uniform, high-quality drying means less food loss and more upcycling. REV™-dried byproducts can be transformed into value-added ingredients, further lowering a facility’s total carbon footprint.

Why prioritize low-carbon drying in food processing now?

Regulations tighten. EU CBAM taxes imports. US SEC rules loom.

Consumers pick green. 65% pay more per Nielsen.

Competitive edge grows.

What industries benefit most from low-carbon drying?

- Snacks and ingredients: High volume.

- Herbs and spices: Export focus.

- Proteins and fruits: Premium margins.

- Pet food: Growing green demand.

REV™ technology is scientifically validated as one of the lowest-carbon, highest-efficiency industrial drying options available today. Switching from freeze or air drying to REV™ directly and quantifiably reduces energy costs and emissions while improving product yield and quality.

FAQ

What drying method has the highest carbon footprint?

Freeze drying at 5-10 kWh/kg and long cycles. Emits 2.5-5 kg CO2 per kg.

Does air drying have low emissions?

No. Long hours offset low kWh/kg.

Can drying impact Scope 3 emissions?

Yes. Lighter products cut shipping 50-70%.

Further Reading

- PMC: Drying Energy Comparisons https://pmc.ncbi.nlm.nih.gov/articles/PMC7602416/

- PMC: Novel Drying Techniques https://pmc.ncbi.nlm.nih.gov/articles/PMC7554907/

- EnWave REV™ https://www.enwave.net/about/rev/

- Anuga FoodTec: REV Sustainability https://www.anugafoodtec.com/magazine/revolutionizing-food-dehydration.php

- EPA Food Processing Emissions https://www.epa.gov/system/files/documents/2023-05/food-processing-emissions.pdf