What is vacuum freeze drying?

In food processing and preservation, various drying technologies compete to offer the best solution for manufacturers seeking to extend shelf life while preserving product quality. Among these technologies, vacuum freeze drying, but is it always the optimal choice for your production needs? This article explores the science behind vacuum freeze drying, its applications, advantages, limitations, and how it compares to more alternatives like microwave dehydration technology.

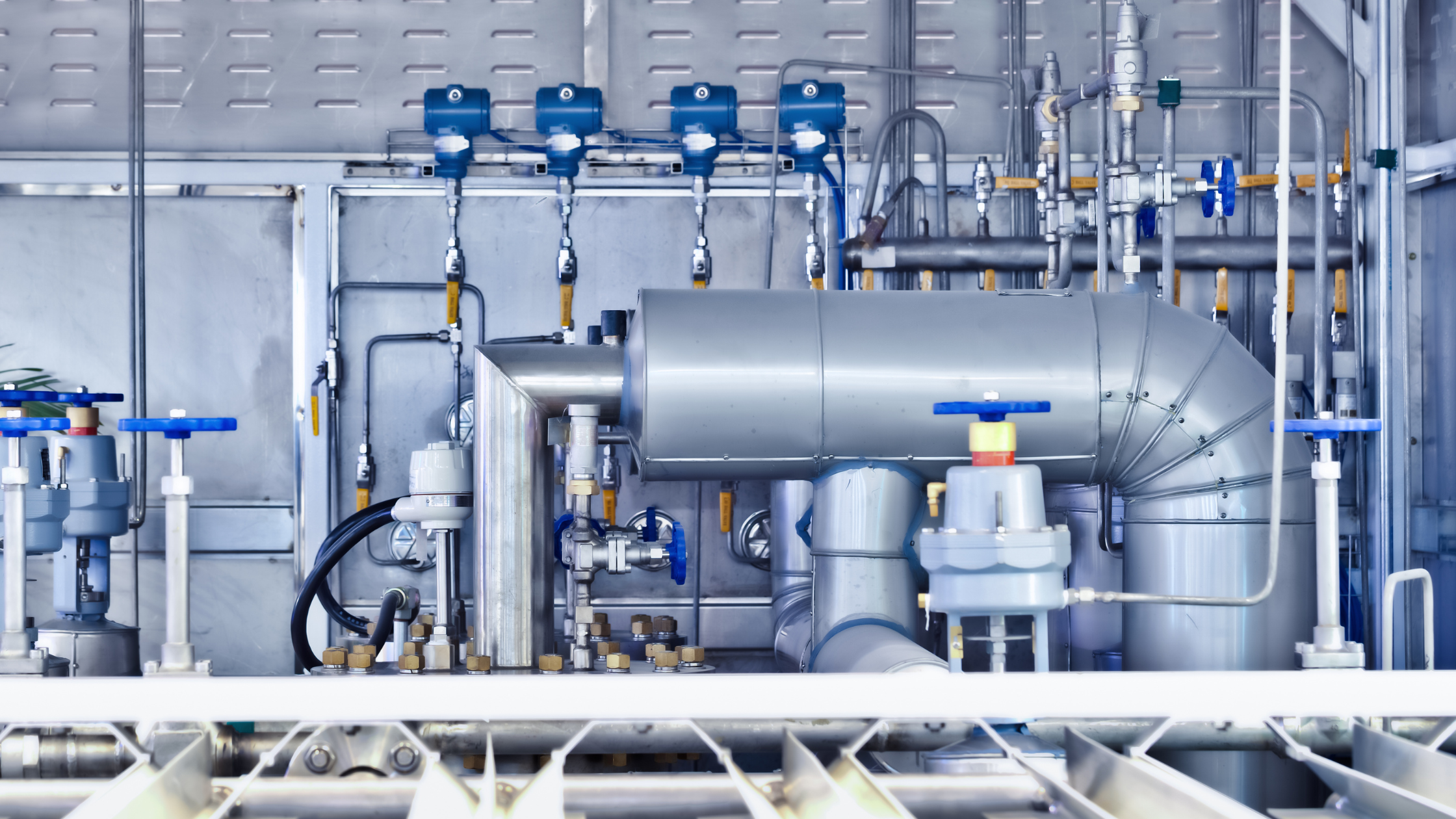

The role of vacuum in freeze drying

Vacuum technology serves as the backbone of the freeze drying process. Its functions include:

Creating the Pressure Differential: By lowering the pressure within the drying chamber, vacuum pumps reduce the boiling/sublimation point of water, allowing ice to convert directly to vapor at temperatures well below 0°C.

Vapor Removal: As water molecules sublimate from the product, vacuum pumps continuously remove these vapors, maintaining the pressure gradient necessary for continued sublimation.

Temperature Control: The vacuum environment helps prevent heat damage by allowing sublimation to occur at low temperatures, preserving heat-sensitive compounds.

Most industrial freeze dryers employ a combination of vacuum pump technologies to achieve and maintain these precise conditions:

- Rotary vane pumps often serve as backing pumps

- Roots blowers provide high pumping speeds during peak sublimation

- Oil diffusion pumps or dry screw pumps may be used in larger systems

How microwave dehydration works with vacuum

Microwave dehydration combines the quality benefits of vacuum drying with the speed and efficiency of microwave energy. Here’s how the process works:

- Products are placed in a vacuum chamber where pressure is reduced, though not necessarily to the extreme levels required by conventional freeze drying.

- Instead of relying solely on conductive heating, microwave energy is applied directly and uniformly throughout the product.

- The microwave energy selectively targets water molecules, causing them to vibrate and efficiently convert to vapor.

- The vacuum environment facilitates rapid moisture removal while maintaining relatively low product temperatures.

This combination creates a fundamentally different drying mechanism that preserves many quality attributes while dramatically improving processing efficiency.

Microwave vs. Freeze Drying: How heating methods differ

While both technologies use vacuum environments, their heating mechanisms create stark contrasts:

| Factor | Vacuum Freeze Drying | Microwave Dehydration (REV™) |

|---|---|---|

| Heat Source | Conductive/radiant tray heating | Targeted microwave energy penetrating the product |

| Temperature | Frozen (-50°C) to gradual warming (0-40°C) | Consistent 30-40°C throughout |

| Moisture Removal | Sublimation of ice crystals over hours/days | Direct vaporization of water molecules in minutes |

| Energy Use | High (1.2+ kWh/kg) due to prolonged vacuum upkeep | Low (0.7 kWh/kg) with rapid cycles |

Traditional freeze dryers struggle with dense or thick products where heat transfer slows drying. REV™’s microwave approach eliminates this bottleneck by heating water molecules uniformly, regardless of product geometry. Additional comparison factors include:

Product quality

Vacuum Freeze Drying: Excellent quality preservation with minimal heat damage and good structural integrity.

Microwave Dehydration: Maintains comparable quality attributes for many products, with excellent color retention, nutrient preservation, and flavor profiles. The faster process can actually better preserve certain volatile compounds that might slowly degrade during lengthy freeze drying cycles.

Production flexibility

Vacuum Freeze Drying: Primarily batch-oriented with limited flexibility for continuous operation.

Microwave Dehydration: Offers greater flexibility, with some systems capable of semi-continuous or continuous operation, allowing for more responsive production planning.

Capital investment and operating costs

Vacuum Freeze Drying: High initial investment with substantial ongoing operational costs related to energy consumption, maintenance, and extended production times.

Microwave Dehydration: While still representing a significant capital investment, the substantially lower operating costs and higher throughput often result in a much more favorable return on investment.

Partnering for innovation in dehydration technology

Implementing advanced dehydration technology requires more than just equipment—it demands expertise, ongoing support, and a collaborative approach to product development. EnWave Corporation offers comprehensive partnership opportunities for companies looking to enhance their dehydration capabilities.

Collaborative product development

The transition to new drying technology often requires product-specific process optimization. EnWave’s experienced food scientists and process engineers work closely with partners to:

- Develop optimal processing parameters for specific products

- Conduct scale-up trials to ensure commercial viability

- Address formulation challenges unique to different product categories

- Optimize rehydration properties when relevant

Technology access models

Recognizing that different companies have varying needs and resources, EnWave offers flexible technology access models. These include equipment purchase for in-house production, toll processing partnerships, technology licensing arrangements, and royalty-bearing commercial licenses. This range of options ensures businesses of all sizes can access EnWave’s innovative dehydration technology in a way that aligns with their specific operational requirements and financial considerations.

Ongoing technical support

Implementing advanced dehydration technology represents a significant operational shift. EnWave provides comprehensive support throughout the equipment lifecycle, including:

- Installation and commissioning assistance

- Operator training programs

- Routine maintenance support

- Process optimization consultation

- Troubleshooting assistance

When evaluating dehydration technologies, product-specific considerations should guide decision-making. While vacuum freeze drying remains valuable for certain ultra-premium applications, microwave dehydration technologies like REV™ often provide a more balanced approach to quality preservation and operational efficiency.

Contact us today to discuss your specific product development needs, food processing challenges, or dehydration technology questions. Whether you’re looking to enhance existing product lines or develop innovative dried food snacks, our team can help you navigate the transition to more efficient drying technology.