Benefits of combining freeze drying with vacuum microwave dehydration for manufacturers

Quality preservation during product drying has always presented a dilemma for companies working with sensitive materials. Whether you’re processing delicate food ingredients, critical pharmaceutical compounds, or biotechnology products, the choice often comes down to speed versus quality. Conventional freeze drying (lyophilization) delivers excellent results but demands significant time and energy investments that can strain production budgets and timelines. Recent advances in drying technology are changing this landscape. By combining freeze drying with vacuum microwave dehydration, manufacturers can achieve faster processing while maintaining the high-quality standards that industries demand.

What is freeze drying and why is it used?

A lyophilizer, or freeze dryer, is a specialized machine used to remove water from products by freezing them and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to vapor. This method is highly effective for preserving the structure, nutrients, and flavors of sensitive materials. It’s widely used in food processing, pharmaceuticals, and biotechnology for products that require long shelf life and high quality.

Key benefits of freeze drying (lyophilization)

- Superior quality preservation: Maintains color, flavor, aroma, and nutrients.

- Extended shelf life: Low final moisture content inhibits microbial growth and enzymatic reactions.

- Gentle on sensitive compounds: Low temperatures protect heat-sensitive ingredients.

- Clean label appeal: No need for preservatives or additives.

Common limitations of freeze drying

- Long processing times: Traditional freeze drying can take many hours or even days to complete a single batch.

- High energy use: Maintaining low temperatures and a high vacuum for extended periods is energy-intensive.

- Batch processing: Most lyophilizers operate in batch mode, which can limit throughput and flexibility.

- Equipment investment: Commercial freeze dry machines and industrial freeze dryers require significant capital outlay and maintenance.

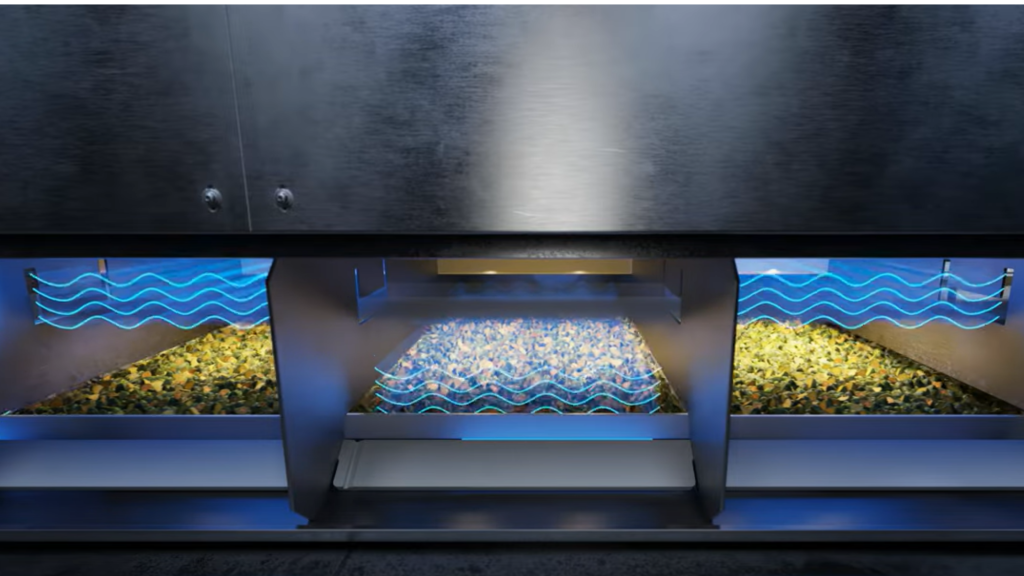

How vacuum microwave dehydration enhances freeze drying

To address the speed and efficiency challenges of freeze drying, manufacturers are now integrating vacuum microwave dehydration (VMD) as a secondary step. This two-step process leverages the strengths of both technologies:

- Freeze drying (FD): The product is first frozen and partially dried under vacuum, removing a significant portion of the water content while preserving structure and sensitive compounds.

- Vacuum microwave dehydration (VMD): The partially dried product is then transferred to a VMD unit, where microwaves under vacuum efficiently remove the remaining moisture. This step dramatically accelerates drying without exposing the product to damaging high temperatures.

Key benefits of combining freeze drying and vacuum microwave dehydration

1. Significantly reduced drying times

By using VMD as a secondary step, manufacturers can cut total drying times by over 75% compared to freeze drying alone. This means faster turnaround, increased throughput, and the ability to respond quickly to market demands—crucial for commercial food drying, product development, and food innovation.

2. Enhanced energy efficiency and sustainability

Shorter drying times translate to lower energy consumption. The efficient use of both freeze dryers and VMD equipment helps reduce operational costs and environmental impact, supporting sustainability goals for food tech and pharmaceutical manufacturers alike.

3. Superior product quality

The gentle, low-temperature process of freeze drying, followed by the rapid, uniform drying of VMD, helps preserve natural color, flavor, aroma, and nutrients. This is essential for dried fruit snacks, specialty ingredients, and sensitive pharmaceutical compounds.

4. Improved consistency and scalability

VMD provides uniform heating, minimizing temperature gradients and reducing the risk of uneven drying or product damage. This consistency is vital for manufacturers producing at scale, where batch-to-batch variability can impact quality and yield.

5. Flexibility across product categories

The FD + VMD process is adaptable to a wide range of products, from food and nutraceuticals to pharmaceuticals and biotechnology. It’s especially valuable for heat-sensitive or delicate materials that require careful handling.

6. Potential for continuous processing

While traditional freeze drying is typically a batch process, integrating VMD can help enable more continuous workflows, improving overall efficiency and reducing downtime.

Limitations to consider with lyophilizers and hybrid drying

While the combination of freeze drying and vacuum microwave dehydration offers many advantages, there are still some limitations to keep in mind:

- Initial equipment investment: Both lyophilizers and VMD units require capital investment and technical expertise.

- Process complexity: Integrating two drying steps requires careful process control and validation, especially for regulated industries.

- Not universally applicable: Some products may not be suitable for microwave energy due to their composition or structure.

- Training and maintenance: Operators must be trained on both systems, and regular maintenance is essential for optimal performance.

Research and industry adoption

The benefits of combining freeze drying with vacuum microwave dehydration are supported by research and real-world industry adoption:

- Studies in ScienceDirect and PubMed demonstrate that this hybrid process can reduce drying times by over 75% while preserving product quality.

- Technology leaders like GEA have shown that the FD + VMD approach allows for continuous processing, improved energy efficiency, and consistent quality in both food and pharmaceutical applications.

- Projects funded by the European Economic Area Grants have developed affordable, small-scale hybrid units for food businesses, demonstrating energy savings and improved product quality for a range of applications.

Accelerate your growth with EnWave

Manufacturers searching for commercial freeze dry machines, industrial freeze dryers, or advanced food dehydration solutions have more options than ever before. The combination of freeze drying and vacuum microwave dehydration represents a significant leap forward for those seeking to improve efficiency, sustainability, and product quality. By reducing drying times, lowering energy use, and maintaining the integrity of sensitive products, this hybrid approach is opening new doors in food innovation, pharmaceuticals, and beyond.

Whether you’re focused on product development, food processing, or commercial food drying, investing in the right drying technology can transform your business. EnWave’s Radiant Energy Vacuum (REV™) technology offers a scalable, patented solution that delivers unmatched speed, quality, and cost savings. With a global network of partners and a track record of successful product launches, EnWave is ready to help you transform your drying process and bring your next big idea to market.

Ready to explore the benefits of microwave drying for your business?

Contact EnWave today to learn more about REV™ technology and see how we can support your product innovation journey.

Further Reading: