Does freeze drying kill bacteria?

Many people believe that freeze drying destroys bacteria. The logic seems sound; low temperatures, vacuum pressure, and moisture removal should make any microbial life impossible. Yet, while freeze drying (also called lyophilization) stops bacteria from actively growing, it doesn’t necessarily kill all of them. The process removes water from food in a frozen state, turning ice into vapor through sublimation. This absence of moisture delays spoilage and limits bacterial activity, but it doesn’t guarantee microbial inactivation. Once water is reintroduced, surviving bacteria can become active again.

This misunderstanding matters because the assumption that freeze drying sterilizes food can lead to false safety assurances in both home and commercial settings. In reality, freeze drying preserves structure and nutrients better than most methods, but it is not inherently a microbial kill step.

What really happens during freeze drying?

Freeze drying is popular across pharmaceuticals, functional food, and ingredients manufacturing because it stabilizes heat-sensitive products. However, it works primarily by preserving, not sterilizing.

The steps are straightforward: freezing, primary drying (where sublimation removes most water), and secondary drying (which removes bound moisture). These phases create an environment where most microbes cannot grow, but they can survive.

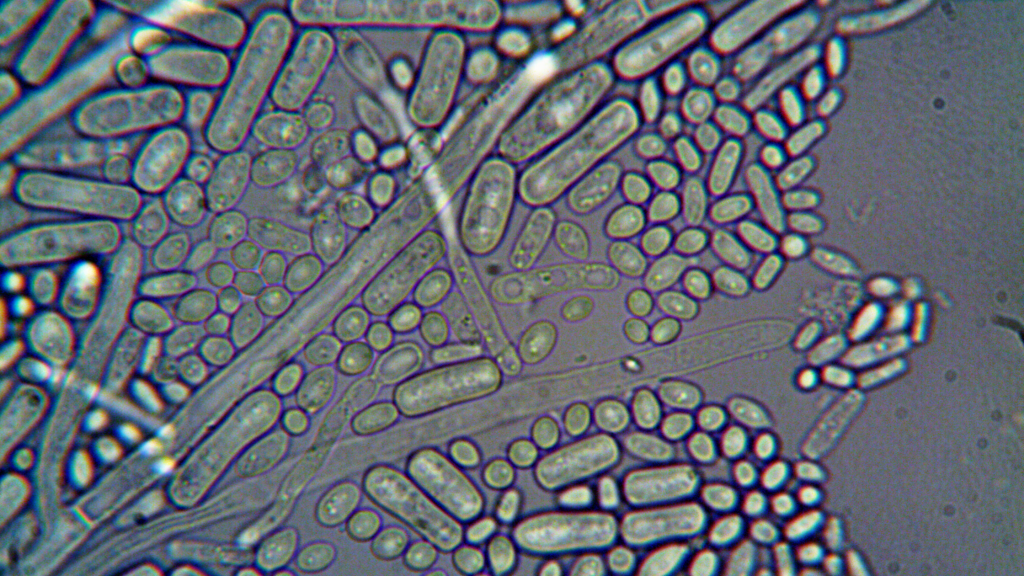

Studies show that microbial survival post-freeze drying depends on several key factors:

- Type of microorganism: Spore-forming bacteria like Bacillus or Clostridium can withstand extreme cold and desiccation.

- Composition of the food matrix: Fat, carbohydrates, and proteins can shield cells from stress, acting as protectants.

- Freezing rate: Rapid freezing forms small ice crystals that damage fewer cells, while slow freezing may preserve bacterial membranes.

- Residual water activity: Even tiny amounts of moisture allow dormant bacteria to persist in inactive form.

According to research published in Cryobiology and the National Institutes of Health, freeze drying often reduces viability rather than eliminates it. For example, probiotic Lactobacillus rhamnosus can maintain up to 15% survival after freeze drying—even when temperature and drying cycles are optimized (NIH Study, 2025).

Similarly, E. coli, Salmonella, and Campylobacter have shown resilience under freeze-dried conditions because of their protective outer membranes and ability to survive long-term dehydration (Empire Freezing & Drying, 2023).

This resilience is useful in biotechnology—freeze drying microbial cultures is an effective preservation technique for labs—but it underscores why food safety protocols require more than low temperature and vacuum alone.

Bacteria can survive, but not thrive

Fresh foods provide moisture-rich environments where microbes grow and multiply quickly. Freeze-dried foods remove that essential moisture, creating inhospitable conditions. Yet even without growth, viable bacteria can remain dormant for years if not destroyed through other controls.

A 10-year study on microbial survival after freeze drying found that:

- Gram-positive species like Corynebacterium and Streptococcus showed survival rates up to 80% after drying.

- Gram-negative species like E. coli experienced lower rates, around 50% initially, stabilizing near 10% over time (Miyamoto-Shinohara, 2000).

Essentially, the process pauses bacteria instead of eliminating them. Once freeze-dried material absorbs humidity or contacts liquid again, the surviving microorganisms may revive.

This makes proper pre-processing and post-drying handling essential.

The importance of pre-processing in microbial reduction

To make dried food products both safe and stable, bacterial challenges must be addressed before dehydration begins. Freeze drying is most effective when combined with hygiene controls and, where possible, additional kill steps.

Common approaches include:

1. Blanching or mild thermal treatment

Applying quick heat denatures enzymes and destroys surface microbes without significant nutrient loss. For produce like vegetables or herbs, blanching prior to drying dramatically improves microbial profiles.

2. Sanitation and washing

Removing soil residues and organic matter cuts contamination levels from pathogens such as Listeria or Salmonella. Even fresh fruit used for freeze drying should undergo chlorinated or ozonated rinses before freezing.

3. Controlled freezing rates

Fast freezing produces smaller ice crystals, reducing cell damage that might shield bacteria. Structured freezing ensures fewer microenvironments where microbes can survive.

4. Cryoprotectants and stabilizers

Ironically, these are important for beneficial bacteria like probiotics but less desirable for general foods. Agents such as skim milk powder or trehalose protect cell membranes, improving bacterial survival rate under extreme vacuum, as shown in multiple studies on Lactobacillus species. In functional foods, this property is used strategically but for other applications, careful control is critical.

Each of these pre-treatment stages can boost the hygienic safety of a freeze-dried product before packaging. However, they don’t change the fundamental limitation: freeze drying itself is not bactericidal.

Introducing microwave dehydration as a next-generation solution

As the food industry demands cleaner production, faster throughput, and safer microbial control, new technologies are emerging to bridge the gaps left by traditional methods. Among them, microwave dehydration under vacuum, also known as Radiant Energy Vacuum (REV™) technology, represents a significant step forward in how moisture removal and microbial safety co-exist in modern food processing.

Unlike freeze drying, microwave dehydration applies controlled electromagnetic energy in a low-pressure environment. The vacuum reduces the boiling point of water, allowing it to evaporate at lower temperatures while microwaves heat moisture evenly throughout the product.

This internal, uniform heating means REV™ can both dry and inactivate bacteria more effectively, reducing viable counts that typically endure during freeze drying.

Key advantages for microbial safety include:

- Rapid moisture removal: Shorter cycles reduce the total time products spend in conditions where airborne or surface contamination might occur.

- Mild but effective heat exposure: Low average temperature with localized molecular agitation disrupts bacterial membranes and denatures essential enzymes.

- Oxygen-free environment: The vacuum minimizes oxidation, retaining product color, flavor, and nutritional value while contributing to microbial inactivation.

- Homogeneous drying: Because energy penetrates volumetrically, no cold spots exist for bacteria to persist in.

Laboratory trials at EnWave’s pilot facility have demonstrated microbial load reductions equivalent or superior to conventional drying steps while maintaining sensory quality in delicate materials such as fruits, herbs, and dairy inclusions.

Balancing safety, quality, and nutrition

The strength of EnWave’s technology lies in how it balances pathogen control and nutrient preservation. Traditional thermal drying methods achieve bacterial reduction but can alter flavor and degrade vitamins or volatile compounds. Freeze drying preserves nutrients but fails to achieve sterility.

REV™ technology achieves both. By applying microwaves under vacuum conditions, water removal occurs quickly enough to suppress microbial recovery while avoiding scorch or nutrient loss. This is particularly valuable for high-value or biologically active ingredients like functional powders, dairy snacks, or protein-based formulations.

Moreover, operating under a vacuum ensures that heat transfer is efficient and consistent across all product particles, eliminating the risk of microbial hotspots.

How drying speed affects microbial stability

One of the most overlooked advantages in microwave drying equipment is its sheer speed. Where freeze drying requires up to two days per batch, microwave vacuum systems can process products in a fraction of that time.

For example, fruit powders or protein snacks that might take 24 hours in a commercial freeze dryer can reach the same final moisture level in one to two hours in a REV™ system. Shorter exposure times mean fewer contamination opportunities from equipment surfaces or airborne particulates.

From a commercial food drying perspective, this efficiency supports not only throughput but also cleaner microbiological profiles by minimizing post-processing handling.

The result: Safer, fresher-tasting products with extended shelf life and consistent quality, without the extreme energy footprint of freeze drying.

Practical strategies for food innovators

For product developers, controlling microbial activity during food dehydration is understanding the whole workflow from raw material to final packaging.

Here are practical recommendations based on current industry and research insights:

- Verify microbial load before and after drying

Baseline testing identifies whether bacteria are already present and provides measurable benchmarks for process improvement.

- Combine sanitation with drying optimization

Using REV™ technology alongside pre-processing controls (washing, UV sanitation, or thermal steps) ensures maximum microbial safety without overprocessing ingredients.

- Use pilot scale trials before scaling

Facilities like REVworx (EnWave’s toll drying and trial center) allow brands to experiment with cycle times, vacuum pressure, and moisture targets while collecting microbial data.

- Store under strict humidity control

Even well-dried materials can reabsorb water, reactivating dormant bacteria. Proper packaging materials and controlled storage environments are essential.

Innovation grounded in science

Scientific studies reinforce the microbial resilience behind freeze drying and why complementary technologies matter. ScienceDirect and PubMed research confirm that Gram-positive strains can withstand desiccation over long durations, while yeast and molds exhibit species-specific resistance depending on residual sugar and fat content (Cryobiology Journal, 2000).

By leveraging EnWave’s patented REV™ systems, manufacturers replace uncertainty with control, achieving microbial safety levels previously attainable only through more energy-intensive thermal sterilization or pasteurization systems.

Microwave dehydration doesn’t compete with freeze drying, it builds on it. What freeze drying started in preservation, microwave drying completes through precision engineering, turning dehydration into a true food tech solution for safety, efficiency, and sustainability.

Advancing safety through precision drying

Freeze drying is an incredible preservation tool, but it doesn’t kill all bacteria. It halts their activity by removing water, leaving some resilient species dormant until moisture returns. This limitation, though well known to microbiologists, often surprises product developers working toward global food safety standards.

Modern alternatives like EnWave’s microwave drying equipment give food processors a new level of microbial assurance without sacrificing product quality. By combining mild temperatures, vacuum precision, and rapid drying, manufacturers can confidently achieve what freeze drying alone cannot, a cleaner, safer, and more efficient process for shelf-stable innovation.

Food innovators around the world now view microwave dehydration not just as a production upgrade but as a critical tool in building the future of safe, functional, and sustainable food systems.

Discover how EnWave helps brands improve both microbiological safety and product excellence through advanced food innovation and commercial food drying. Learn more at enwave.net.

Further Reading

- National Institutes of Health, “Impact of Freezing and Freeze Drying on Lactobacillus rhamnosus GG Survival” (2025): https://pmc.ncbi.nlm.nih.gov/articles/PMC12111118/

- Cryobiology, “Survival Rate of Microbes After Freeze Drying and Long-Term Storage” (2000): https://pubmed.ncbi.nlm.nih.gov/11161557/

- Empire Freezing & Drying, “Does Freeze Drying Kill Bacteria?” (2023): https://empiredrying.com/does-freeze-drying-kill-bacteria/

- Green Thumb Depot, “Can Bacteria Survive Freeze Drying?” (2024): https://greenthumbdepot.com/blogs/guides/does-freeze-drying-kill-bacteria

- National Library of Medicine, “Survival of Freeze-Dried Bacteria” (JSTAGE, 2008): https://www.jstage.jst.go.jp/article/jgam/54/1/54_1_9/_article

- EnWave Corporation, “Freeze-Drying vs. Dehydrating: What’s the Difference?” (2025): https://www.enwave.net/freeze-drying-vs-dehydrating-whats-the-difference/