Breaking down the myths around microwave drying technology

Many traditional drying methods have stood the test of time. Techniques like freeze-drying and conventional air drying are widely used across industries, but newer innovations, such as microwave-assisted drying, are often misunderstood. Misinformation and myths can cloud the real benefits of this advanced technology. Today, we’re setting the record straight and diving into the latest research to explore how microwave drying, particularly Enwave’s patented Radiant Energy Vacuum (REV™) technology, offers unmatched performance, nutrient retention, and sustainability.

Myth #1: Microwave drying destroys nutrients

One of the most pervasive myths about microwave drying is that it destroys the nutrients in food. This misconception likely stems from early studies on home microwaving, which focused on overheating rather than controlled microwave-assisted drying processes.

Recent research, however, tells a different story. Studies like the one published in the Journal of Food Processing and Preservation emphasize that properly calibrated microwave drying can actually retain or even enhance nutrient profiles. Unlike traditional methods that rely on prolonged heat exposure, microwave drying uses electromagnetic energy to evaporate moisture quickly, reducing nutrient degradation.

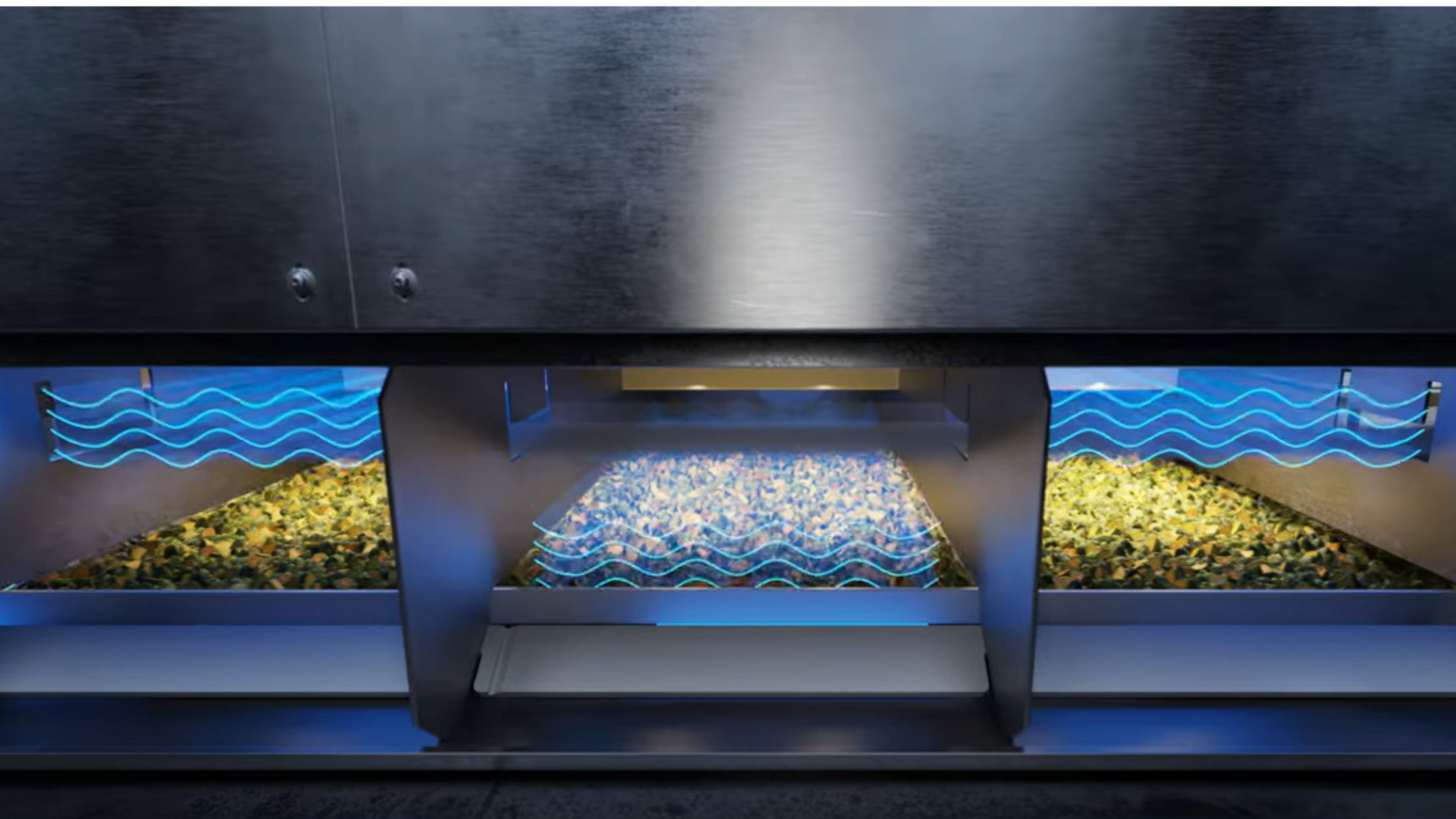

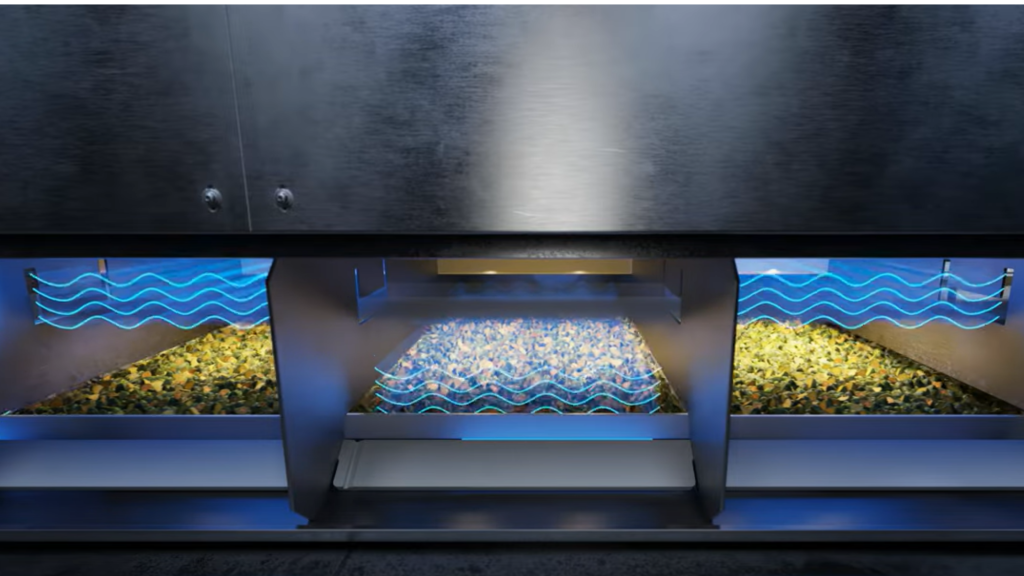

REV technology takes this process a step further. By combining vacuum pressure with microwave energy, REV operates at lower temperatures, helping retain sensitive nutrients such as vitamins, antioxidants, and polyphenols. This makes REV an ideal solution for producing nutrient-dense foods, from dried fruit snacks to plant-based protein powders.

Myth #2: Microwave drying is inefficient compared to freeze-drying

Another common myth is that microwave drying can’t compete with freeze-drying in terms of quality or efficiency. While freeze-drying has long been the gold standard for preserving structure and nutrients, it’s an energy-intensive process with high production costs.

Microwave-assisted drying, especially with Enwave’s REV technology, offers a faster, more efficient alternative. Unlike traditional freeze-drying, which can take anywhere from 24 to 48 hours, REV can dry products in a fraction of the time. This rapid drying process helps retain texture, flavor, and appearance while using significantly less energy, making it a more sustainable option.

For example, REV technology has been successfully used to create shelf-stable, crispy fruit snacks that retain their vibrant colors and natural sweetness without added sugars or preservatives. The ability to preserve both nutrients and sensory qualities makes REV a versatile choice for food processors seeking innovation in product development.

Myth #3: Microwave Drying isn’t safe

Safety concerns are another barrier preventing widespread adoption of microwave drying. Some worry that exposure to microwave energy could harm the food or create safety risks in production facilities. However, these fears are unfounded.

Microwave drying systems, like those powered by REV technology, are carefully engineered to ensure safety at every stage. The microwaves used in commercial drying are tightly controlled and operate within specific parameters to avoid overheating or uneven drying. Additionally, the vacuum component of REV technology lowers the boiling point of water, allowing for gentle, low-temperature drying that minimizes thermal damage.

Research from the National Center for Biotechnology Information (NCBI) supports the safety of microwave drying, highlighting its efficiency in moisture removal without compromising food safety. (Source: NCBI Article on Microwave Drying)

A patented solution with proven results

Enwave’s REV technology stands apart from other microwave drying methods due to its unique combination of microwave energy and vacuum pressure. With 17 patents and applications in over 20 countries, REV has been validated across multiple industries, from food and nutraceuticals to pharmaceuticals.

One key advantage of REV is its scalability. Whether you’re producing small batches for niche markets or large quantities for commercial food drying, REV systems can be customized to meet your needs. This flexibility, combined with energy efficiency and faster drying times, offers a competitive edge over traditional drying technologies.

Success stories

Many companies have already harnessed the power of REV technology to bring innovative products to market. For instance, REV-dried blueberries retain up to 97% of their original anthocyanin content (a key antioxidant) compared to significantly lower retention rates in air-dried or conventional oven-dried fruit.

Similarly, REV has been used to develop plant-based meat alternatives with improved texture and flavor. By preserving the integrity of plant proteins during drying, REV helps create products that mimic the juicy, satisfying bite of real meat, a game-changer in the growing food tech space. Learn more about our partners here.

The sustainability factor

In today’s food industry, sustainability is a priority. Traditional drying methods often consume large amounts of energy and water, contributing to a higher carbon footprint. REV technology addresses these concerns by offering a more eco-friendly solution.

By reducing drying times and energy consumption, REV systems can lower operational costs and improve overall sustainability. This makes it easier for food processors to meet environmental, social, and governance (ESG) goals while delivering high-quality products.

Why microwave drying is the future of food processing

The food industry is evolving rapidly, driven by changing consumer preferences, technological advancements, and a growing demand for sustainable practices. Microwave drying, particularly Enwave’s REV technology, is at the forefront of this transformation.

By debunking myths and embracing science-backed innovations, we can unlock new possibilities for food processing, product development, and beyond. Whether you’re looking to create nutrient-packed dried snacks, extend the shelf life of fresh produce, or explore novel applications in food tech, microwave drying offers a reliable, efficient, and sustainable path forward.

For more information on Enwave’s patented REV technology and its applications, explore our website or contact us.