A drying solution for yeast and nutraceutical innovation

Food technology is evolving at a remarkable pace. One area drawing more attention is yeast, the essential ingredient behind breads, beers, dietary supplements, and countless bioactive products. The yeast market is thriving globally, propelled by its flexible applications and the steady growth of consumer demand for natural, high-nutrient ingredients. Recently, Canadian bakers highlighted the importance of yeast quality on platforms like CBC, reminding us that even subtle changes in yeast behavior can reshape entire product categories. While local bakers focus on recovering the freshness in bread loaves, manufacturers and product innovators worldwide are exploring how yeast’s true potential hinges on better drying technology.

Vacuum Microwave Dehydration is emerging in the market for those searching for alternatives to commercial freeze drying and other legacy methods. This article will explore how this technology suits product development, food processing, and nutraceutical innovation, illustrated by scientific insights and real-world results from EnWave’s quanta REV™ system.

Yeast market momentum and applications

The yeast market is set for robust expansion, with an expected compound annual growth rate of about 8.79% between 2024 and 2031. Bakery products still claim the lion’s share, but the versatility of yeast is being tapped in beverages, biofuels, animal feeds, and especially nutraceuticals. Europe currently leads the yeast ingredients space thanks to advanced bakery technology and strong demand for premium baked goods. Asia-Pacific’s adoption of nutritional products is driving the fastest growth.

For Canada, clean-label and organic trends are reshaping how yeast-derived ingredients perform. Consumers are turning their backs on additives and processed ingredients, and yeast fits perfectly among options that boost nutrition and help manufacturers deliver on transparency. Saccharomyces cerevisiae, the yeast species found in bakers yeast, offers high concentrations of protein, vitamins, and minerals. This quality has made it indispensable for dietary supplements and functional foods, pushing the lines between food, health, and pharma.

Yeast drying results at a glance

Drying yeast is a delicate process. Drying yeast effectively means more than just removing water. The process must preserve the live, active culture that is essential for product function. EnWave’s research compared freeze drying and vacuum microwave dehydration using the quanta REV™ system:

- Sample and Process: Fresh compressed yeast was divided. One batch was dried with REV™, the other with traditional freeze drying.

- Testing: Moisture content was measured before and after drying. Each sample (FD and REV) was rehydrated and tested for colony forming units per gram (CFU/g) using standard plating methods.

Key results

- Moisture content: Yeast achieved 6.87% final moisture after REV™ processing, matching industry targets for shelf stability.

- Drying speed: REV™ dried the yeast in just 1.5 hours. Freeze drying took well over a day. This means REV™ can finish 32x faster, dramatically improving throughput.

- Viability (CFU/g):

- Fresh yeast: 2.754×10^10 CFU/g

- REV™ dried: 2.142×10^10 CFU/g

- Freeze dried: 8.874×10^9 CFU/g

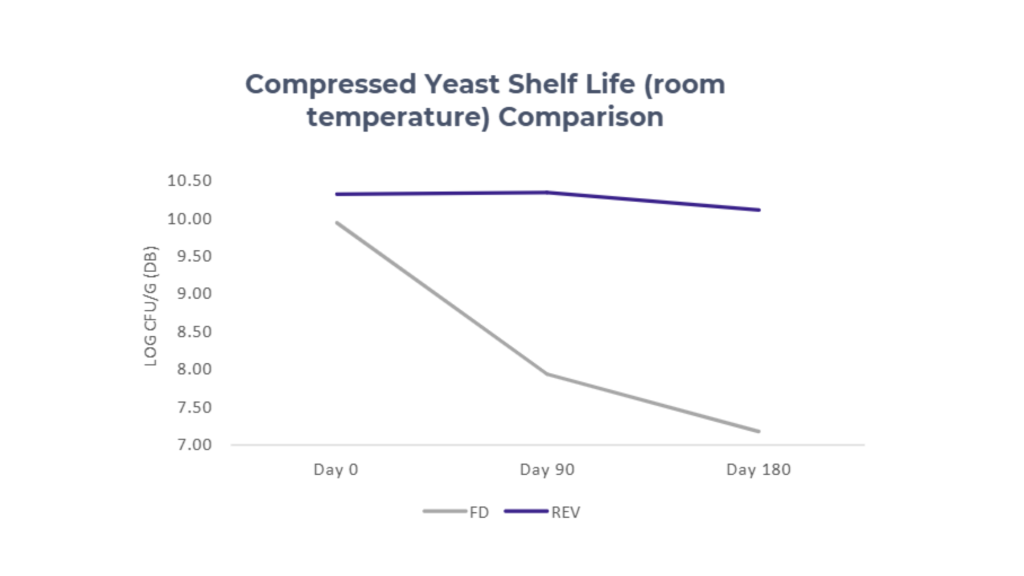

- Shelf Life: The REV™ dried yeast retained nearly all viability after 180 days in storage. In contrast, freeze dried yeast lost more live cells over the same period.

How REV™ compares to Freeze Drying

For those comparing commercial freeze drying with modern vacuum microwave dehydration, the advantages are clear:

Microwave drying equipment delivers rapid, even energy. Microwave energy penetrates deeply into the product, drying it evenly throughout while preserving the bioactivity critical for nutraceuticals and supplements.

Energy efficiency

Microwave systems use less energy than freeze drying. Unlike traditional methods, there’s little wasted heat or lost operational time.

スケーラビリティ

REV™ equipment can be used for small batch R&D or expanded for commercial food drying lines, giving product developers full flexibility.

Product innovation

The ability to retain natural color, flavor, and nutrient potency supports clean-label trends. Batch-to-batch consistency also means brands can scale without quality dips.

Nutritional, sensory, and stability benefits

Vacuum microwave dehydration does more than save time. It supports innovation in nutraceuticals and food processing where maintaining nutrient integrity is vital. Compared to freeze drying, microwave dehydration offers :

- Higher retention of protein and bioactive compounds.

- Less degradation of sensitive nutrients, antioxidants, and vitamins.

- Superior shelf-life stability, key for supplements and health-formulated products.

- Minimized flavor and aroma losses due to gentler heat conditions.

These results matter for formulators seeking natural, clean-label solutions, and they’re central to EnWave’s portfolio of case studies and R&D collaborations.

Clean label demands shaping the future

Global trends show clean label products are mainstream. Nearly half of shoppers choose foods with transparent sourcing, minimal ingredients, and no artificial additives. Nutraceuticals and dietary supplements have followed suit, favoring processes that preserve naturalness without chemical additives.

Vacuum microwave dehydration directly supports these priorities. Unlike chemical preservatives or harsh thermal treatments, REV™ uses precise controls to keep yeast functional, nutrient-rich, and free of unwanted process byproducts. This gives food brands and supplement makers a real competitive edge in a crowded market.

Regional and application opportunities

Canada’s position in the global yeast and nutraceutical industry is strengthening. The country benefits from trends in plant-based foods, organic farming, and bioactive ingredient sourcing. Vacuum microwave dehydration aligns perfectly with these strengths:

- Food tech innovations support sustainable production and better utilization of Canadian agricultural resources.

- Commercial food drying can be more efficient and lower in energy use, supporting both cost reduction and sustainability goals.

- Active ingredient development for supplements and functional foods relies on scalable, reproducible drying technologies to meet global regulations.

Next-Gen drying technology for better nutraceuticals

EnWave’s yeast drying project is a prime example of product innovation fueled by advanced drying technology. By putting the science to the test, the team demonstrated how vacuum microwave dehydration compares freeze drying; delivering better yeast viability, faster production, and longer shelf-life. This benchmark sets the stage for broader adoption in nutraceuticals.

Vacuum microwave dehydration brings together what matters : product consistency, maximum nutritional value, speed to market, and real shelf stability. As consumer demand for clean-label, high-function foods grows, REV™ stands out as the technology forward-thinking companies need to consider. For those seeking microwave drying equipment advantages, improved efficiency over commercial freeze drying, or simply a better way to scale product development, EnWave offers solutions proven to help you compete in today’s food tech landscape.

For formulators, R&D teams, and product developers:

- Review case studies to learn how leading food brands have transformed their ingredient drying: enwave.net/case-studies.

- Request a demo and discuss your specific product needs with our technical experts: enwave.net/contact.

- Explore food innovation that’s truly commercial-ready: enwave.net/solutions/product-development.

Further Reading:

- EnWave Corporation, Freeze Drying vs Microwave Drying: https://www.enwave.net/freeze-drying-vs-microwave-drying/

- Market Insights: https://www.grandviewresearch.com/industry-analysis/food-dehydrators-market & https://www.futuremarketinsights.com/reports/food-dehydrators-market

- Clean Label Trends: https://foodchainmagazine.com/the-future-of-clean-label-ingredients-in-food-production/

- CBC yeast market article: https://www.cbc.ca/news/canada/bread-fixing-website-1.7631445