Food processing solutions you need to watch

From the supermarket to your pantry, nearly every snack or meal passes through some form of advanced processing, finding the right balance between taste, nutrition, and minimizing waste is no small feat. In 2025, the most forward-thinking companies are constantly experimenting with new drying technologies, reimagining how foods retain color, crunch, nutrients, and flavor. Today’s innovative solutions, from next-generation microwave drying equipment to fermentation and plant-based ingredient tech, are reshaping product development and bringing new possibilities to the table.

The rise of functional foods

Consumers are prioritizing wellness, looking beyond basic nutrition to snacks and meals that offer extra benefits like immune support, gut health, or cognitive focus. Functional foods now appear everywhere, from adaptogen-fortified bars to beverages with probiotics and botanicals. In fact, global surveys show more than one-third of buyers now seek out products for emotional wellbeing, while interest in functional snacks and mood-supporting ingredients is at an all-time high.

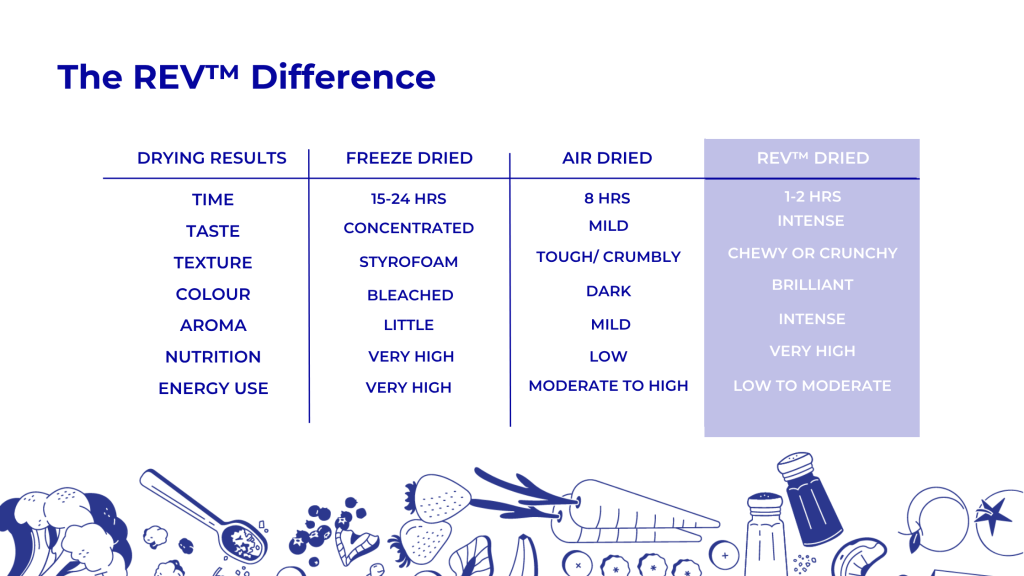

Brands must meet this demand with products that are both convenient and reliably nutritious. Processing methods make all the difference, gentle dehydration techniques, for instance, help preserve sensitive vitamins and active compounds in functional snacks, while industrial freeze dryers and commercial freeze drying often rely on methods that trade speed for higher energy costs and environmental footprint.

Alternative proteins keep momentum

Alternative proteins are no longer fringe. Pea, soy, lentil, mycoprotein, microalgae, and even precision-fermented proteins are surging in popularity, with growth fueled by both sustainability goals and consumer curiosity. Product innovation in this category demands drying technology that gently stabilizes these ingredients, preserving texture and color without sacrificing protein quality.

Microwave drying equipment answers these needs with efficient, scalable solutions that offer more consistent results than many traditional machines. Processes like vacuum microwave dehydration enable the creation of shelf-stable, plant-based snacks and intricate ingredients, delivering protein-rich bites that meet the demand for both taste and nutritional quality.

Key factors for product developers

- Versatility: Supports a wide range of protein sources and formats.

- Clean Label: Facilitates fewer additives and processing aids.

- Energy Use: Significantly lower consumption and shorter drying cycles compared to commercial freeze dryers.

The fermentation revolution

Fermented foods have captivated both chefs and consumers lately, from kombucha and kimchi to miso, sauerkraut, cheese, and plant-based yogurts. These products stand out for their flavor and probiotic benefits, but they also present unique processing challenges, probiotics and beneficial enzymes can be easily destroyed by harsh drying conditions.

Gentle, low-oxygen dehydration, such as vacuum microwave drying, helps preserve the microbial cultures and delicate flavors that make fermented products unique. Commercial food drying solutions that overly rely on high heat may not be able to guarantee probiotic viability or vibrant colors. Microwave drying systems enable product innovation in this fast-evolving space, supporting the rise of shelf-stable, fermented snacks and upcycled ingredients.

Mood-boosting snacking

Modern snackers want more than great taste, they want mood-supporting benefits, ingredients tailored to emotional wellbeing, and functional claims backed by science. Foods and drinks with natural adaptogens, botanicals, vitamins, and minerals are seeing explosive growth, especially as consumers turn to food for mental-health support.

To retain these sensitive active compounds, processors must avoid methods that use extended heat or oxygen exposure. Microwave drying offers rapid, uniform dehydration at lower temperatures, helping maintain the bioactivity of mood-boosting ingredients and providing a clean-label solution that meets consumer expectations.

Traditional freeze drying strengths, weaknesses, and trade-offs

Commercial freeze dryers, also known as industrial freeze dryers or lyophilization machines, have long been prized for their ability to remove water with minimal heat exposure, preserving delicate structures and flavors. However, they come with limitations:

- High energy consumption and long cycle times. Studies show freeze drying can use over 15kWh for a standard cycle, while vacuum microwave drying achieves similar results using less than 2kWh.

- Processing times can extend to several days, making this approach less efficient for high-volume or fast-moving product lines.

- Texture is often crisp but can be spongy; certain fruits, for instance, may appear pale or less visually appealing compared to microwave-dried equivalents.

With sustainability and efficiency in mind, many brands are seeking alternatives that keep product quality high while reducing costs, energy, and time.

Where microwave dehydration fits in

Microwave dehydration, especially in vacuum conditions, is attracting food innovators because it delivers more speed, greater control over product texture and moisture, and smarter energy use. Below are key advantages supported by research, industry experience, and brands adopting this drying technology:

- Rapid, even drying complete in minutes, not days

- Better color and flavor retention, yielding shelf-stable snacks and ingredients that look fresh and vibrant

- Stronger nutrient preservation, ideal for functional and clean-label product development

- Greater energy and operational savings compared to commercial freeze drying or convective dryers

For product categories ranging from dried fruit snacks to high-protein bites, plant-based meals, and infused mood foods, microwave drying equipment delivers the flexibility, efficiency, and quality markets now demand.

Market Trends Shaping the Food Tech Landscape

Innovation in food processing doesn’t happen in a vacuum, it follows consumer behavior, health research, and global priorities. As we look further into 2025 and beyond, several powerful trends are driving change across the food industry. From clean label demands to experimental textures and nutrient-dense snacking, today’s product developers are navigating a fast-changing landscape, and the tools they use to process ingredients are more important than ever.

Here are five key trends shaping the future of food processing and product innovation:

Transparent sourcing and clean labels

More than ever, consumers are reading ingredient lists. Clean label isn’t just about removing artificial additives; it’s about building trust. According to multiple global surveys like this one from Innova Market Insights, transparency around ingredient origin, processing methods, and sustainability efforts are major purchase drivers.

Food processors need equipment that supports this demand. Technologies like vacuum microwave dehydration help minimize or eliminate the need for stabilizers, color additives, or artificial preservatives. By gently removing moisture while preserving better natural color, flavor, and texture, processors can market products closer to their original ingredients, and meet consumer calls for honesty and simplicity across the label.

Gut health and functional snacking

Digestive wellness is now mainstream, and snacks are doing more than curbing hunger. From probiotics and prebiotics to fiber-rich ingredients and fermented functional foods, gut health is becoming a central pillar of modern nutrition. According to Mintel, there’s explosive demand for shelf-stable products that include ingredients like chicory root, kefir, yogurt cultures, or functional bacteria.

This is where processing meets protection. Many functional ingredients, especially live cultures and bioactive compounds, are sensitive to heat and oxygen. Using microwave-based dehydration at moderate temperatures and in low-oxygen environments helps preserve sensitive compounds that would otherwise degrade in conventional hot-air or spray-drying systems.

Hybrid products

The line between snacks, supplements, and meals continues to blur. Consumers are exploring “hybrid” formats like protein-infused chips, plant-based yogurt bites, and cheese crisps with added probiotics or adaptogens. Texture is critical here. Whether it’s a crunch that rivals fried snacks or a chew like a dried fruit leather, the eating experience can make or break a new product launch.

Vacuum microwave technology gives processors precise control over product texture. A fruit snack can be puffed for crispness, or slightly chewy for a whole fruit feel. Plant-based protein chips can be dried in such a way that the structure is preserved without heavy oils or frying. These features simply aren’t available with many traditional freeze drying machines or other conventional drying systems, which are more limited in their control over finished product textures.

Upcycling and Ingredient waste reduction

Food waste is now a frontline issue. Many brands are turning agricultural blemishes, byproducts, or overlooked ingredients into valuable elements of their product line. Apple peels, carrot pulp, spent grains, or even unused dairy like whey can all be upcycled into snacks, powders, or inclusions for baked goods.

But upcycled ingredients often have high moisture content and short shelf life unless processed immediately. This is where drying technology becomes mission critical. The ability to quickly and gently dry upcycled material (without damaging nutrients or flavor) unlocks its potential. Microwave drying systems, especially those using vacuum environments, allow these ingredients to be stabilized and used efficiently, supporting both creativity and climate goals. It’s no surprise that many startups in this space are moving away from batch-based industrial freeze dryers in favor of faster and more efficient equipment that scales with volume and minimizes costs.

Personalized and mood-supporting foods

Not all trending ingredients are about nutrition in the traditional sense. Mood-boosting foods; those rich in magnesium, B vitamins, nootropics, or calming botanicals like ashwagandha continue to grow at a rapid pace, particularly among younger consumers looking for mental wellness support in their snacks and beverages.

These ingredients are often sensitive and require gentle handling. Traditional high-temperature drying could degrade their efficacy, reducing their marketing potential and health benefits. Microwave drying presents a modern solution, efficiently removing moisture while preserving activity, perfect for nutraceutical-style snacks or “gastronomic supplements” designed to feel indulgent and functional at once.

Whether you’re formulating the next big protein crisp, reducing waste through intelligent upcycling, or tapping into the next wave of mood-enhancing foods, drying technology is at the core of food innovation.

Industrial freeze dryers and commercial freeze drying systems still play a role in niche markets, but for those chasing speed, sustainability, and ingredient integrity, microwave vacuum drying is redefining what’s commercially possible. Tailored for today’s health-conscious, planet-focused consumer, this approach offers both flexibility and performance that can help brands stay ahead in a rapidly evolving marketplace.

Bringing it all together

Companies must monitor new drying technologies and rethink legacy methods if they want to compete in the age of functional foods, alternative proteins, and innovative snacking. While industrial freeze dryers and commercial freeze drying systems have their place in food processing, the advantages of modern microwave drying equipment (speed, efficiency, versatility, and higher nutritional retention) give forward-looking brands a crucial edge.

The next wave of food dehydration solutions is here, and it’s making possible a world of products that prioritize both ingredient integrity and sustainability. For those exploring product development in food innovation, food dehydration, or dried fruit snacks, investigating vacuum microwave technology could be the most important move for 2025 and beyond.

Interested in learning more about cutting-edge drying technology, food processing trends, or seeing comparative data and performance results? Check out EnWave’s resources or connect with our team for deeper insights and solution support at enwave.net.